Automation

SmarTram

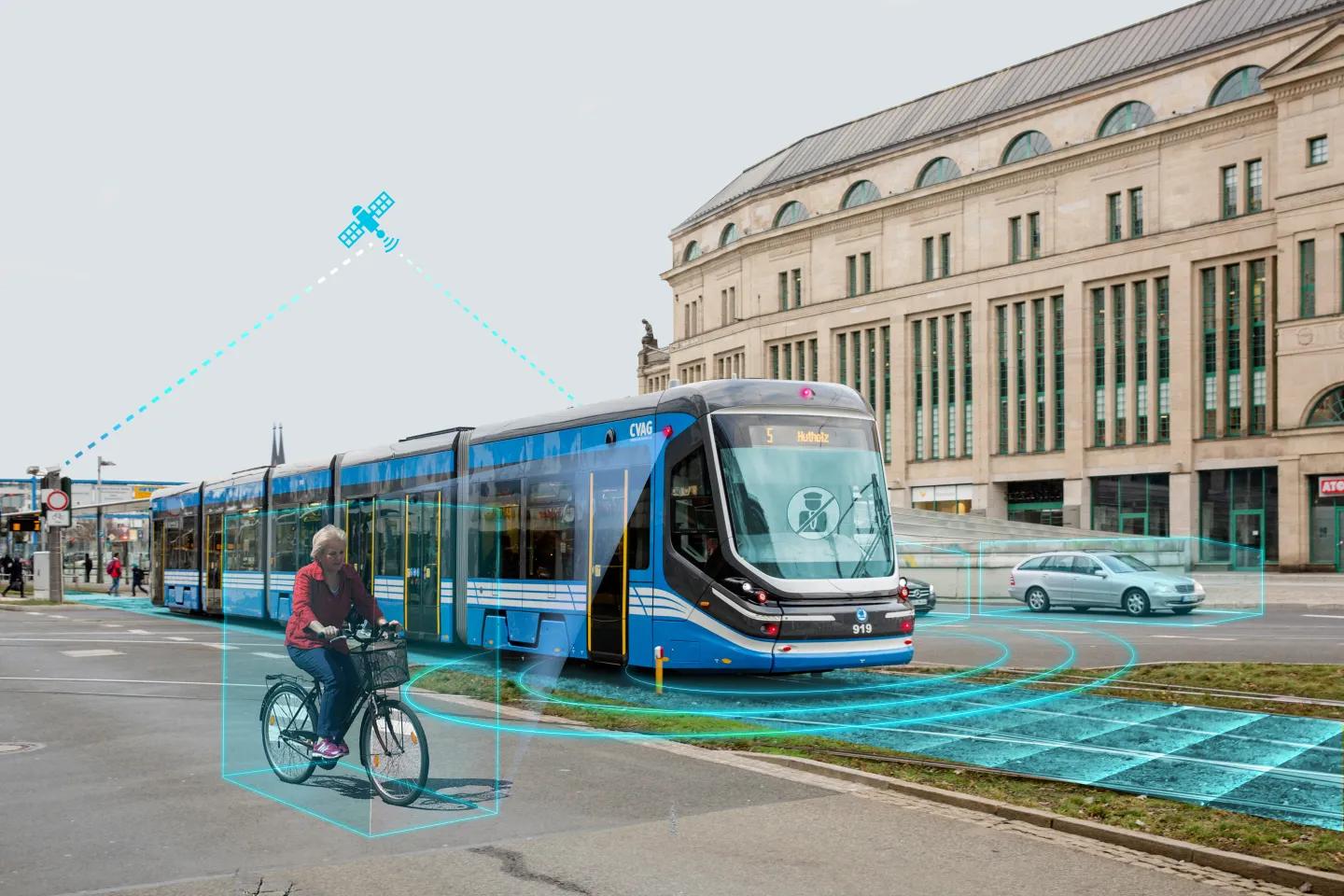

Development of technical solutions for the use of automation potentials in the streetcar sector

Project period: Okt 2022 – Sept 2025 | Project partners: IABG Industrieanlagen-Betriebsgesellschaft mbH, FusionSystems GmbH, Chemnitzer Verkehrs-AG

Work on autonomous driving has been going on for years in the aerospace and automotive industries, as well as in rail transport. This has already been fully implemented in some subways and delimited metro lines. However, current systems usually reach their limits when it comes to increased interactions with other road users, such as on the street or in streetcars.

For this reason, the planned project will develop and improve technical solutions for exploiting automation potential in the streetcar sector. This will be based on architectures and functions that have already been tested in the automotive sector and on the use of infrastructure. The technological focus is on the investigation and further development of hybrid systems including vehicle- and infrastructure-based sensors, the demand-oriented flexibilization of the vehicle and fleet system, the application of V2X communication and cloud computing technologies including the associated security aspects, and the design of the vehicle with special consideration of the passenger and vehicle guidance aspects that autonomous vehicle guidance requires. The practical validation of the technologies is carried out with the help of a streetcar and the operating environment of the Chemnitzer Verkehrs - AG.

Gefördert durch:

RailAIxs

Development of a reference architecture for a vehicle-based environment recognition for driverless rail traffic

Project period: Aug 2022 – Juli 2025 | Project partners: RWTH Aachen, FH Aachen, Qinum GmbH

Today, branch lines are often served by diesel railcars at a low frequency. Due to the unattractive service, passenger numbers remain low and economical operation is often not possible. Freight traffic is often completely discontinued except for the possible service of sidings of large industrial areas. As a result, many branch lines have been taken out of service. Furthermore, it is becoming increasingly difficult to find skilled workers to drive multiple-unit trains. With the introduction of driverless light local railcars, lower operating costs can be achieved and a denser frequency sequence can be offered, which increases the attractiveness of rural local transport. Lightweight construction, small size and a battery-electric drive system also reduce energy requirements compared with today's vehicles.

The aim of the project is the development of a reference architecture for a vehicle-based environment recognition for driverless rail traffic, especially for the application on secondary lines, its implementation and testing being done by means of a demonstrator. The data requirements and the systematic development of innovative possibilities for using and networking the data in the context of the BMVI will be researched.

Gefördert durch:

ESPRIT – completed research project

Note: This project was funded by the European Union's Horizon 2020 Research and Innovation Program under Grant Agreement No. 653395.

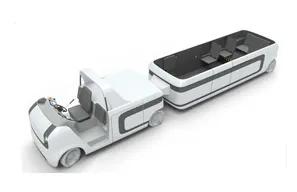

The Easily diStributed Personal RapId Transit (ESPRIT) project aimed to develop a special lightweight L-class electric vehicle that could be stacked together to save space and driven as a road train. It is part of the Horizon 2020 program of the European Union. Up to 8 ESPRIT vehicles can be nested in one truck train to allow efficient fleet redistribution and an intelligent, balanced, and cost-effective transportation system. A total of 20 partners from 7 countries were involved in the project.

- Vehicle development (design, CAD modeling, clutch construction, prototype construction)

- Vehicle Automation

- Vehicle maintenance

Completed research project: People Mover System

About 2 million people make the annual pilgrimage to Mecca for the Hajj, the pilgrimage around the Kaaba. The believers circle the cube-shaped building made of black stone seven times unti-clockwise.

To enable pilgrims with limited mobility to perform the Tawaf and Sa'e (pilgrims walk seven times (4 laps) back and forth between the two mounds Safa and Marwa), an automated system should be developed within the expanded Haram building. In this context, the people movers must be able to handle the high passenger capacity and be deployable without rails and other obstacles for flexible use on the mezzanine (mezzanine and mezzanine floors).

Important design and engineering requirements were to ensure the physical and religious integrity of the Holy Haram, the welfare of the pilgrims, as well as the formal design into the religious environment (shape and color language, details such as ornaments...).

News releases 2021

2021

Alternative Drive Systems

HyTraGen

Hydrogen-Tram for next Generation - Realisierung eines mit Wasserstoff betriebenen Straßenbahnprototyps

Projektzeitraum: Dez 2023- Nov 2026 | Projektpartner: HeiterBlick GmbH, Flexiva Automation & Robotik GmbH, Technische Universität Chemnitz, Görlitzer Verkehrsbetriebe GmbH (assoziiert), Leipziger Verkehrsbetrieb GmbH (assoziiert), CVAG – Chemnitzer Verkehrs – Aktiengesellschaft (assoziiert)

Mit den Projektpartnern wird in dem sächsischen Konsortium Europas erste Straßenbahn mit Wasserstoffantrieb entwickelt und gebaut. Die Erprobung der Straßenbahn erfolgt in Zusammenarbeit mit den Görlitzer Verkehrsbetrieben (GVB). Gefördert wird das Projekt durch das Bundesministerium für Verkehr und Digitales innerhalb des Programmes für „Nationales Innovationsprogramm Wasserstoff- und Brennstoffzellentechnologie Phase 2 (NIP II)“.

Als Fortführung des F&E – Projektes „H2-TRAM“ werden die erlangten Forschungsergebnisse und die neuartigen Systemlösungen in einen prototypischen Versuchsträger überführt. Der Prototyp wird in Leipzig bei der HeiterBlick GmbH gefertigt und anschließend im Betriebsumfeld der GVB getestet. Neben der Validierung der technischen Lösungen und der Funktionalität des Gesamtfahrzeuges, werden auch die Voraussetzungen geschaffen zukünftig BZ – Straßenbahnen einfacher zuzulassen und kostengünstiger zu fertigen.

Die Wasserstoffstraßenbahn sollte dabei nicht in direkter Konkurrenz zu vorhanden Oberleitungsbahnen stehen, sondern vielmehr eine Alternative für neue Strecken darstellen, welche aus ökonomischen, ökologischen und städtebaulichen Gründen nicht mit Oberleitungen ausgerüstet werden können. Ein weiterer positiver Aspekt ist der Wegfall von hohen Infrastrukturkosten für Installation und Wartung der Oberleitung. In einem ganzheitlichen Wasserstoffkonzept mit einer Vielzahl von unterschiedlichen Verbrauchern würde für die nutzenden Städte zudem ein weiteres Energieversorgungssystem entstehen, das nicht netzabhängig ist und überschüssige Elektroenergie in Form von Wasserstoff speichern kann.

Gefördert durch:

HZwo: RAHD

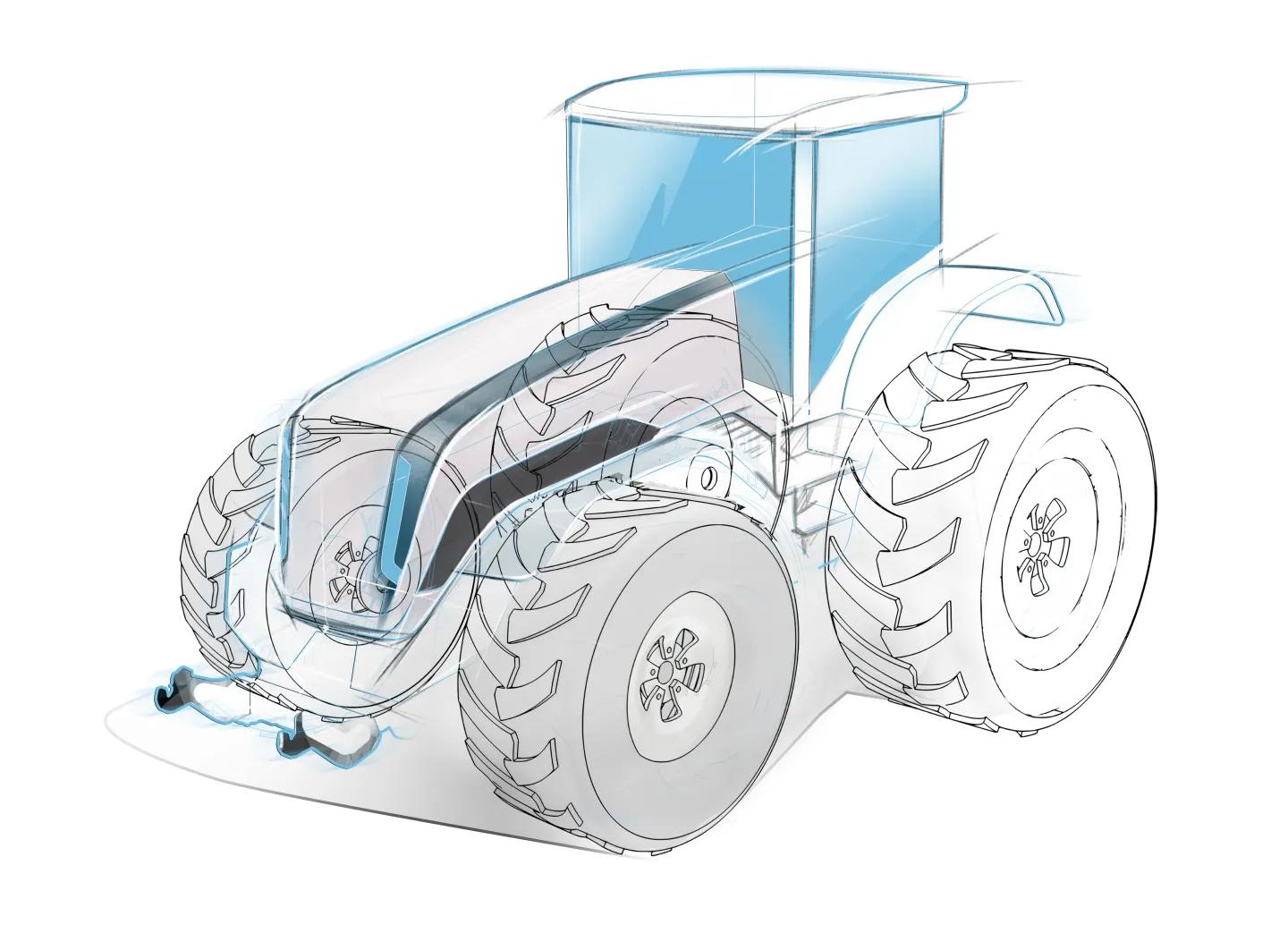

Wasserstoffspeicher- und Elektroantriebsfunktionslösung für schwere brennstoffzellenbetriebene Land- und Forstwirtschaftsfahrzeuge

Projektzeitraum: Sep 2023- Aug 2026 | Projektpartner: LSE-Lightweight Structures Engineering GmbH, EAAT GmbH Chemnitz, Technische Universität Chemnitz, Agraset Agrargenossenschaft eG (assoziiert), EIDAM Landtechnik GmbH (assoziiert)

Aktuelle Anwendungsfelder für Wasserstoffantriebslösungen beschränken auf klassische Fahrzeugtypen, wie LKW, Busse und andere Nutzfahrzeuge. Landwirtschaftliche Fahrzeuge und Maschinen finden in der aktuellen Diskussion wenig Beachtung. Vorhandene Fahrzeugflotten werden heute fast ausschließlich mit fossilen Kraftstoffen, meist Diesel, betrieben. Ein mittelgroßer Betrieb mit 12.000 kW Antriebsleistung in seinem Fuhrpark bringt es dabei auf einen jährlichen Kraftstoffverbrauch von rund 500.000 Litern. An dieser Stelle wird ersichtlich, dass auch in diesem Bereich gehandelt werden muss, um die zukünftigen Klimaziele zu erreichen. Das Forschungsvorhaben beschäftigt sich deshalb mit der Erarbeitung einer neuartigen Wasserstoffspeicher- und Antriebslösung für den Einsatz in landwirtschaftlichen Fahrzeugen. Damit soll es BSZ-Fahrzeugen möglich sein, leistungs- und reichenweitenadäquate Zielwerte der Dieselfahrzeuge zu erfüllen. Die neuartige Lösung soll grundlegend konzipiert und in ein Gesamtfahrzeugkonzept integriert werden. Des Weiteren wird durch den Aufbau eines skalierten Forschungsmodells die Funktionsweise validiert.

Gefördert durch:

Heat2Comfort

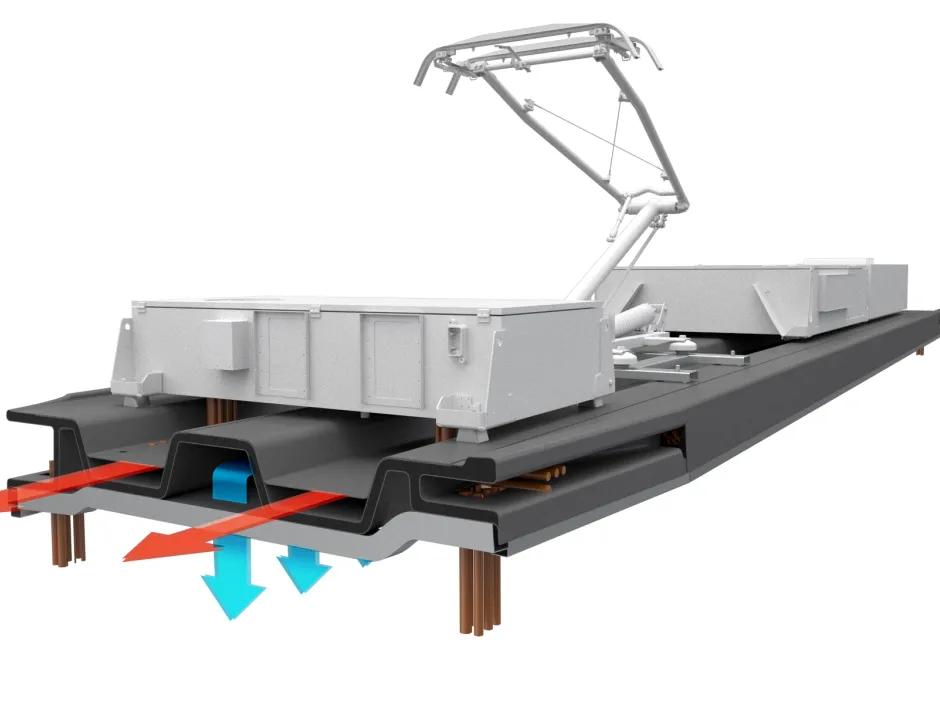

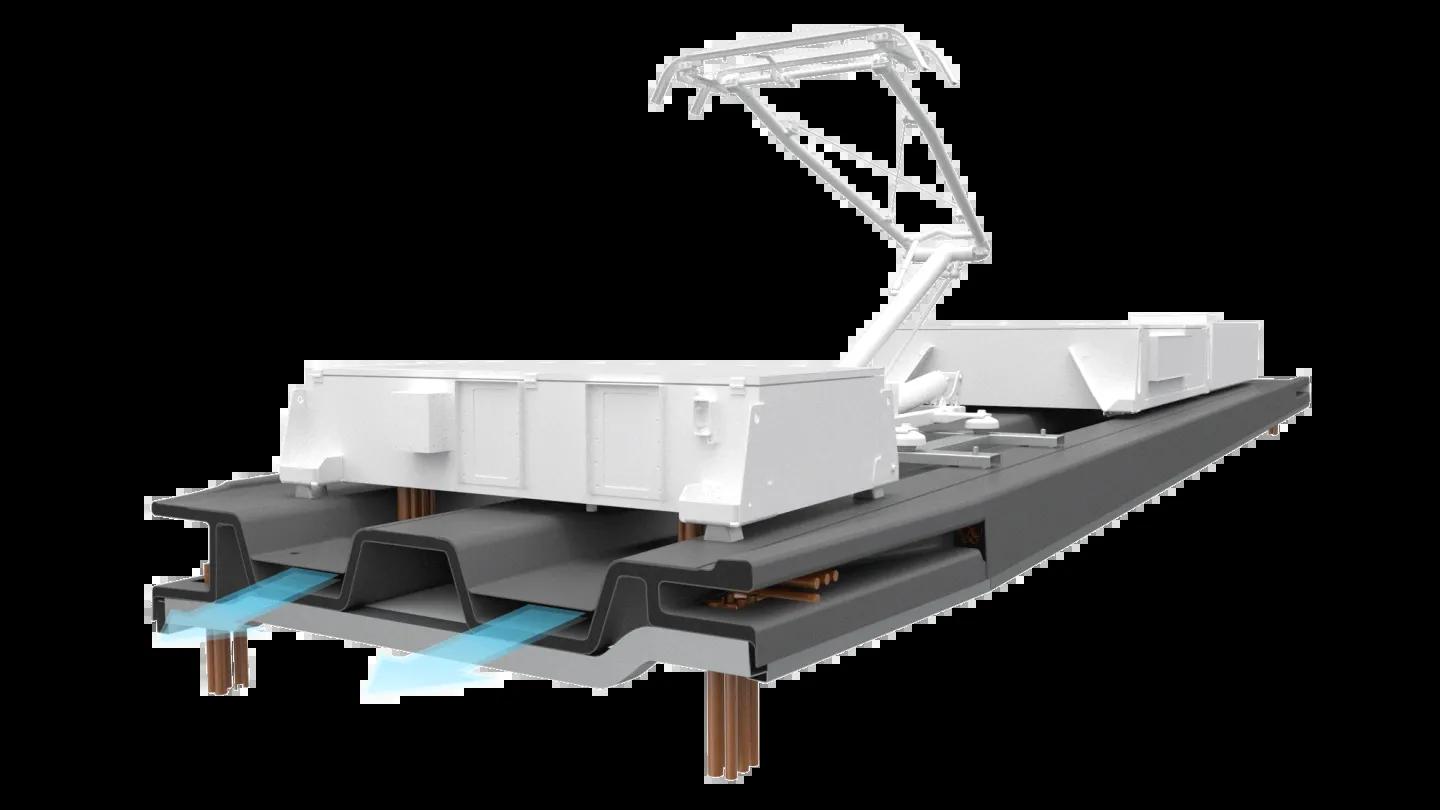

Waste heat-based air conditioning of fuel cell multiple units

Project period: Mar 2021 - Feb 2024 | Project partners: WätaS - Wärmetauscher Sachsen GmbH, ILK - Institut für Luft- und Kältetechnik Gemeinnützige Gesellschaft mbH, Fraunhofer Institute for Manufacturing Technology and Applied Materials Research, DB Systemtechnik GmbH (associated), EAW - Energieanlagenbau GmbH Westenfeld (associated).

The central starting point for waste heat utilization and energy savings is the thermal activation of components in the vehicle interior in order to use their radiation temperature to generate thermal comfort. This eliminates the need for energy-intensive overheating and undercooling of the supply air. The heating and cooling of the interior components is to be achieved using the waste heat from the fuel cell. A further point of research is the investigation of an energy-optimized heat transfer from the fuel cell to the interior in the case of heating operation. On the other hand, the power required for cooling down the interior components is to be generated with the help of the fuel cell waste heat. The fuel cell serves as the vehicle's primary energy conversion system for traction and auxiliary operations. Thus, the provision of waste heat cannot be primarily matched to the heat demand, which is why the integration of a thermal storage unit is necessary. Due to this novel air conditioning concept and the high degree of complexity, a novel control concept is to be implemented, which makes use of a large amount of environmental information and at the same time has a significantly higher number of manipulated variables than today's control algorithms. In addition, machine learning is to be used to enable continuous learning capability and thus optimization of the control software during operation.

supported by:

H2-Tram – completed research project

Innovative streetcars with fuel cell drive

Project period: Dec 2020 - Feb 2023 | Project partners: HeiterBlick GmbH, Flexiva Automation & Robotik GmbH, CVAG - Chemnitzer Verkehrs - Aktiengesellschaft (associated), AVG - Albtal-Verkehrs-Gesellschaft mbH (associated

The use of these novel fuel cell streetcars should enable public transport companies to connect new urban areas with rail vehicles in the future in a sustainable and pollution-free manner, independently of an existing traction power infrastructure, and to integrate them into existing transport hubs or mobility points to be established in the future.

The project was funded by: Federal Ministry for Digital and Transport, PtJ and NOW

Gefördert durch:

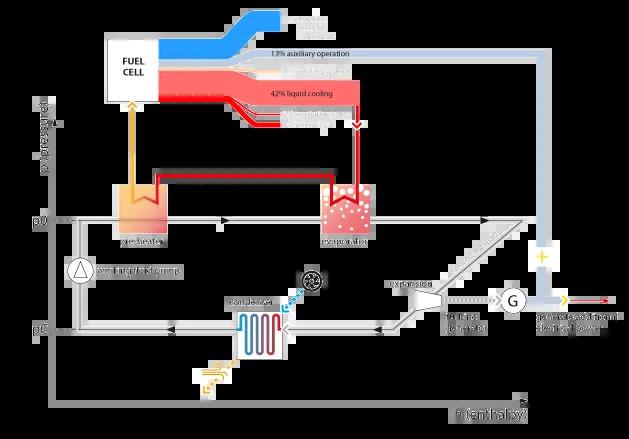

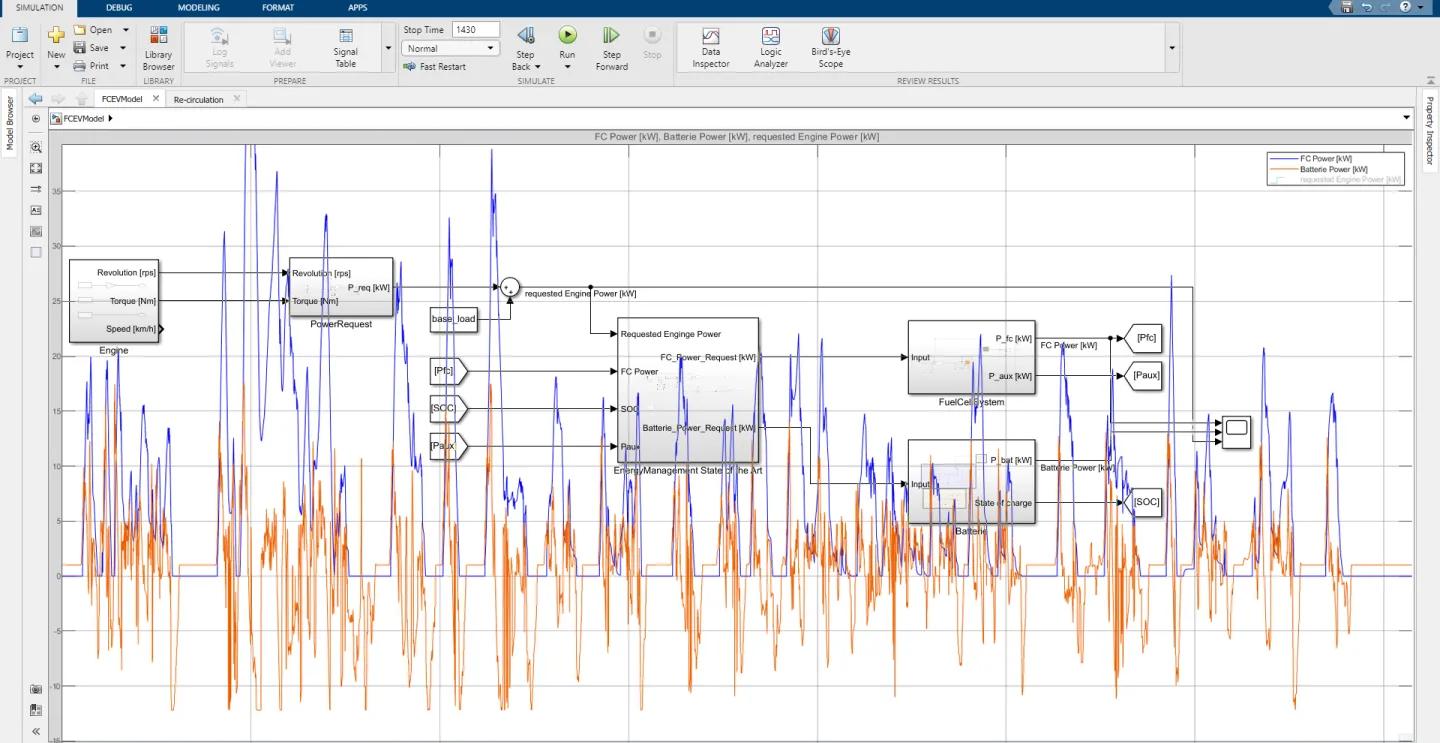

Heat2Power – completed research project

"Efficiency increase and waste heat - refinement for fuel cells in rail vehicles"

Project period: Dec 2019 - Oct 2022 | collaborative partners: WÄTAS and ILK Dresden

In the "Heat2Power" project, possibilities for minimizing the energy requirements of air-conditioning systems while maintaining consistently good passenger comfort are to be researched. At the same time, the connection to the fuel cell waste heat will be examined in order to identify potential savings and to evaluate structural adaptations (e.g. additional weight, space requirements, etc.). Additional thermal inertias and decentralized demand-based room conditioning will be investigated.

An essential approach is the refinement of the fuel cell waste heat by means of an energy conversion system into electrical power, in order to supply the accruing thermal power for the most universal use possible on the vehicle, independent of the respective vehicle air conditioning demand. Furthermore, the primary energy requirement for vehicle air conditioning is to be significantly reduced by coupling the fluctuating heat output of the fuel cell with the interior heating using a decentralized system of heat storage units and heat exchangers.

The project was funded by: ERDF and SAB

EcoCC – completed research project

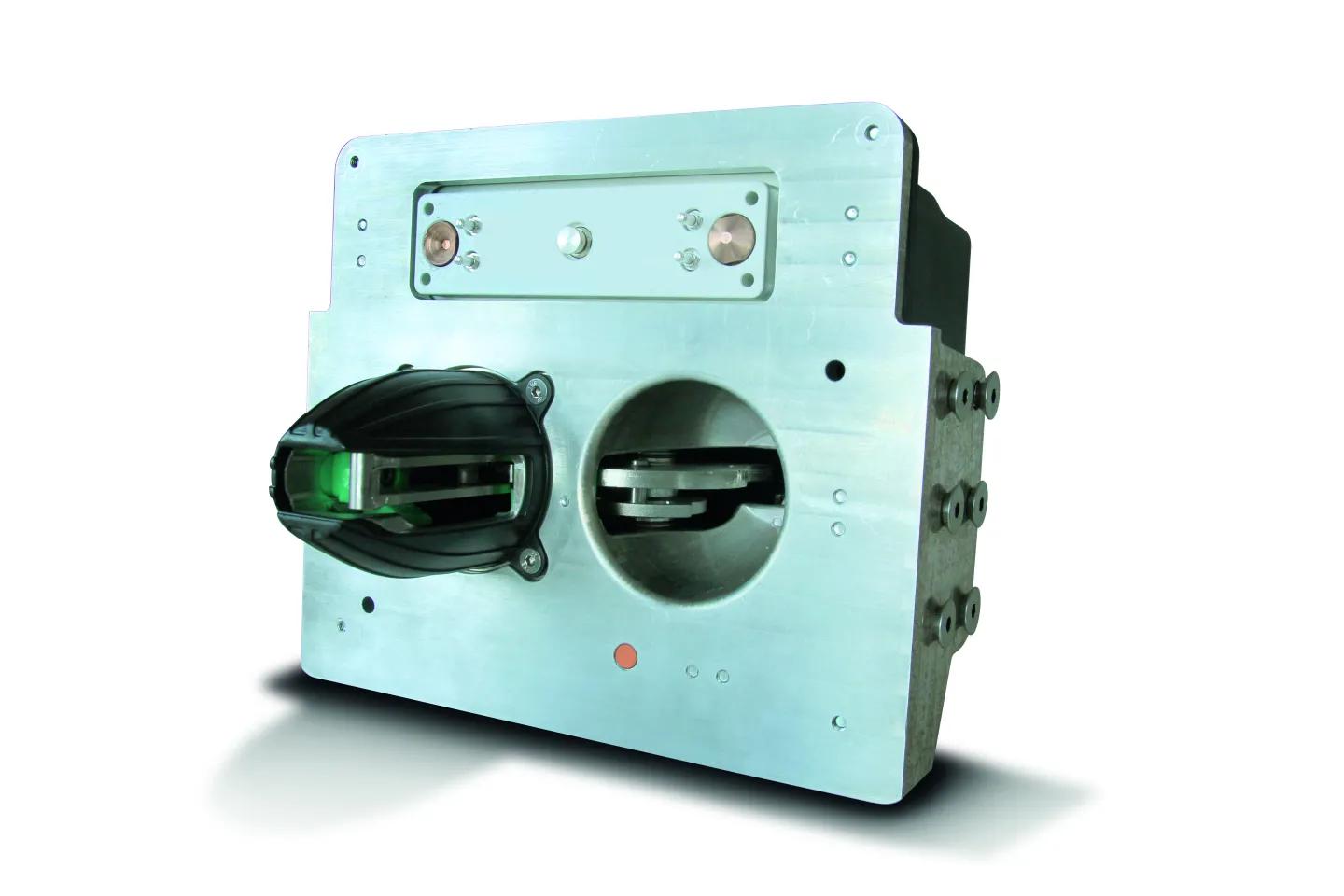

Development of an economical and reliable measurement and control concept for automotive fuel cell systems

Project period: Jan 2019 - Dec 2021 | Partners: Continental, LSA, TU-Chemnitz, Fraunhofer IWU

As part of the HZwo initiative, the EcoCC project is concerned with the development of an economical and reliable measurement and control concept for low-temperature PEM fuel cells in automotive applications. A combination of data from existing, conventional sensors with dynamic models of control engineering allows improved condition monitoring of the system without the need to develop new and expensive hardware. Furthermore, such a mathematical and software-based approach offers the possibility to detect errors or to reconstruct missing data from other measurements. Thus, even existing sensors could potentially be replaced by virtual ones. Professor Streif, head of the Chair of Control Engineering and System Dynamics, therefore sees an enormous potential for cost savings as well as safer and more efficient operation of modern fuel cell systems in the "methods of control engineering and state estimation".

The project was funded by: ERDF and SAB

Innovations

Innovation is the key to efficient and modern mobility. This is why research is such an important component for HÖRMANN Vehicle Engineering as an engineering service provider. In constant exchange with institutes and university facilities, we are on the lookout for new sustainable solutions for tomorrow's mobility. The focus here is on lightweight construction and alternative drive systems, as well as materials research and structural optimization. We help our customers to find the best solutions for greater passenger comfort.

The graphic shows our current research and development projects, with which the preconditions for a rail vehicle of the latest generation can be created. The focus is on lightweight construction with structural and material optimization, the use of alternative drive systems, in particular fuel cell technology, with the aim of increasing efficiency and range.

Lightweight

3-D FiberTrain

Entwicklung eines werkzeuglosen Fertigungsverfahrens zur Herstellung großformatiger und hochbelastbarer Schienenfahrzeugkomponenten

Projektzeitraum: Sep 2023- Jun 2026 | Projektpartner: Fraunhofer IWU, Lakowa Kunststoffbe- und verarbeitungs GmbH, Siemens Mobility GmbH (assoziiert)

Additive thermoplastische Kunststoffverarbeitungsverfahren bieten vollkommen neue Potentiale für eine deutliche Kosten-, Zeit- und Materialeinsparung sowie für eine Verringerung des CO2- Fußabdruckes insbesondere bei kleinen bis mittleren Seriengrößen. Das Forschungsvorhaben zielt auf die Erforschung und Entwicklung einer neuartigen thermoplastischen Technologie, die den Großformat-3D-Druck mit dem 3D-Tapelegeprozess kombiniert und dadurch die werkzeugfreie Fertigung von geometrisch komplexen und hochbelastbaren Großkomponenten für Schienenfahrzeuganwendungen – wie etwa Frontmasken, Dachstrukturen etc. – erlaubt. Der Verzicht auf Formwerkzeuge, der hohe Automatisierungsgrad sowie der Einsatz wiederverwendbarer thermoplastbasierter Ausgangsmaterialien führt unmittelbar zu reduzierten Herstellungskosten und einer deutlich verbesserten Ressourceneinsparung im Gegensatz zur konventionellen Fertigung solcher Schienenfahrzeugkomponenten mit klassischen duroplastbasierten Faserverbundverfahren.

Gefördert durch:

PulPro – SMC

Einsatz von Pultrusion-Profilen in Kombination mit lastpfadgerechten SMC aus recycelten Kohlenstofffasern in Rohbaustrukturen von Schienenfahrzeugen

Projektzeitraum: Okt 2023- Jun 2026 | Projektpartner: Conbility GmbH, Fraunhofer IWU, LSE-Lightweight Structures Engineering GmbH, Modellbau Roth GmbH & Co. KG, Polynt Composites Germany GmbH

Um unterschiedliche Perspektiven und Anwendungen der Querschnittstechnologie Leichtbau zusammenzubringen und weiterzuentwickeln, verbindet das FuE-Vorhaben PulPro-SMC unter Federführung der HVE GmbH gezielt Kompetenzen aus mehreren Leichtbau-Disziplinen mit dem Fokus der ressourceneffizienten – und damit CO2-reduzierten – Herstellung von serienfähigen Strukturbauteilen aus faserverstärkten Kunststoffen für die Massenmärkte auf Straße und Schiene. Speziell die Verknüpfung der sich nach allgemeinem Verständnis eher widersprechenden Bereiche Leichtbau, Crashsicherheit und Wirtschaftlichkeit stellt eine große Herausforderung in dem Projekt PulPro-SMC dar. Angestrebtes Gesamtziel ist die Realisierung einer effizienten und wirtschaftlichen Herstellungstechnologie für faserverstärkte Leichtbau-Fahrzeugstrukturen in einem modifizierten Pultrusionsverfahren in Kombination mit einem lastpfadgerecht verstärkten Recycling-SMC-Formgebungsprozess. Der Technologienachweis soll anhand einer realen Schienenfahrzeugkomponente geführt werden.

Gefördert durch:

LeiPo-3D-FKM

Erschließung neuer Leichtbau-Potenziale durch standardisierte Auslegung von Bauteilen des metallischen 3D-Drucks mittels FKM-Richtlinie

Zur Erreichung der weltweiten Klimaziele gewinnen Energieeffizienz und Ressourcenschonung zunehmend an Bedeutung. Im wichtigen Bereich des metallischen Leichtbaus lassen sich durch zukunftsweisende Produktionsmethoden, wie etwa der additiven Fertigung (AM), außerordentliche Potenziale zu Massereduktion erschließen.

Um eine größere Breitenwirkung für diese fortschrittliche Technologie zu erzielen, muss eine standardisierte Auslegung von additiv gefertigten Komponenten möglich sein. Gerade in konventionell agierenden Sektoren besitzt die Auslegungssicherheit von Bauteilen höchste Bedeutung. Dabei kommt zumeist die FKM-Richtlinie zur Anwendung. Diese beinhaltet für spezifische Materialien belastbare Festigkeitskennwerte unter Berücksichtigung aller Ferti-gungseinflüsse. Der metallische 3D-Druck und dessen zugeordnete Nachbearbeitungsme-thoden finden darin aktuell keine Berücksichtigung, wodurch die Innovationskraft der Fir-men, welche nach FKM auslegen müssen, signifikant begrenzt wird.

Der LeiPo-3D-FKM-Verbund macht es sich zur Aufgabe dieses Problem zu lösen und eine additiv gefertigte Stahllegierung für FKM zu qualifizieren. Dabei sind wichtige Einflussfakto-ren zu Pulverzustand und AM-Anlagentechnik zu berücksichtigen. Weiterhin beeinflussen unterschiedliche Nachbearbeitungszustände die zu erwartende Festigkeit. Hier stehen ins-besondere die Oberflächenglättung und –verdichtung im Fokus der Betrachtung.

Die Anwendungspartner werden dieses gewonnene Wissen im Rahmen des Vorhabens auf repräsentative Technologieträger aus den Bereichen Transportwesen und mobiler Maschi-nenbau übertragen und mit Hilfe repräsentativer Prüfungen validieren.

Gefördert durch:

AnoWaAs

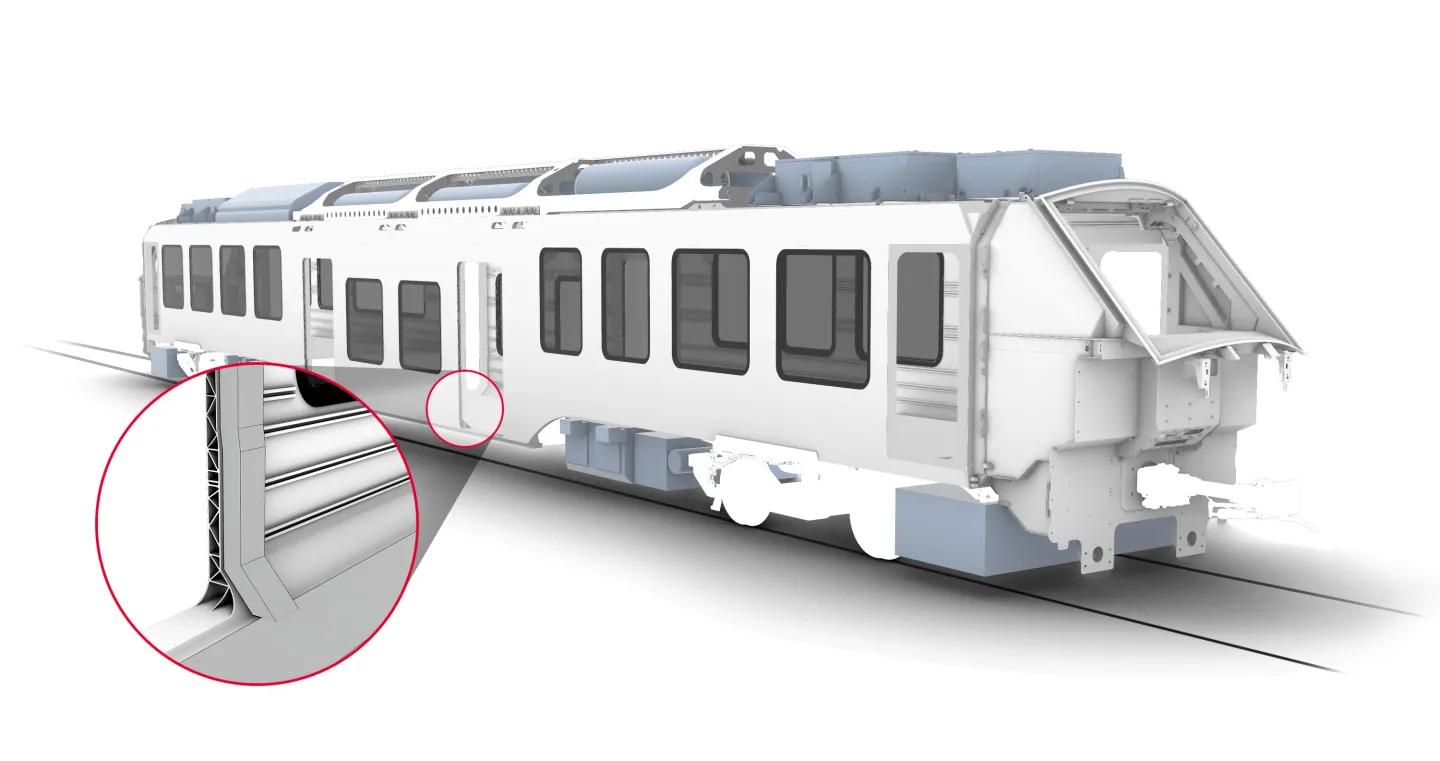

Development of a novel and modular car body for rail vehicles

Project period: Mai 2021 – April 2024 | Project partners: ALSTOM Transport Deutschland GmbH (Konsortialführerschaft), Deutsches Zentrum für Luft- und Raumfahrt e.V., Institut für Fahrzeugkonzepte, Elemag GmbH, GSI mbH Niederlassung SLV Berlin-Brandenburg, Rausch Metalltechnik GmbH, Universität Stuttgart, Institut für Maschinenelemente, 3A Composites GmbH (assoziierterPartner)

Within the scope of the project, a new type of modular car body for rail vehicles is being systematically developed which, in terms of its structure and architecture, is adapted as optimally as possible to alternative drive systems (battery and fuel cell). Due to the associated framework conditions, the optimized and integrated positioning of heavy components, the mechanical car body architecture and significantly lightweight construction, under the prerequisite of cost efficiency, are of particular importance, as are manufacturing, maintenance and recycling. Using a variety of methods, the complete development chain is mapped: from fundamental, process-based packaging studies to construction method developments, novel design and layout procedures, optimized manufacturing and assembly processes, and the prototypical implementation of exemplary components, with lightweight construction always in the foreground. The similarities between commercial vehicle bodies and the bodies of rail vehicles are being exploited and recognized synergies between the two areas are being consistently pursued in both directions. Therefore, the consortium includes partners with expertise in both sectors and beyond. For the reasons given, the results of the envisaged project will contribute to strengthening the German economy in lightweight construction and to CO2 savings.

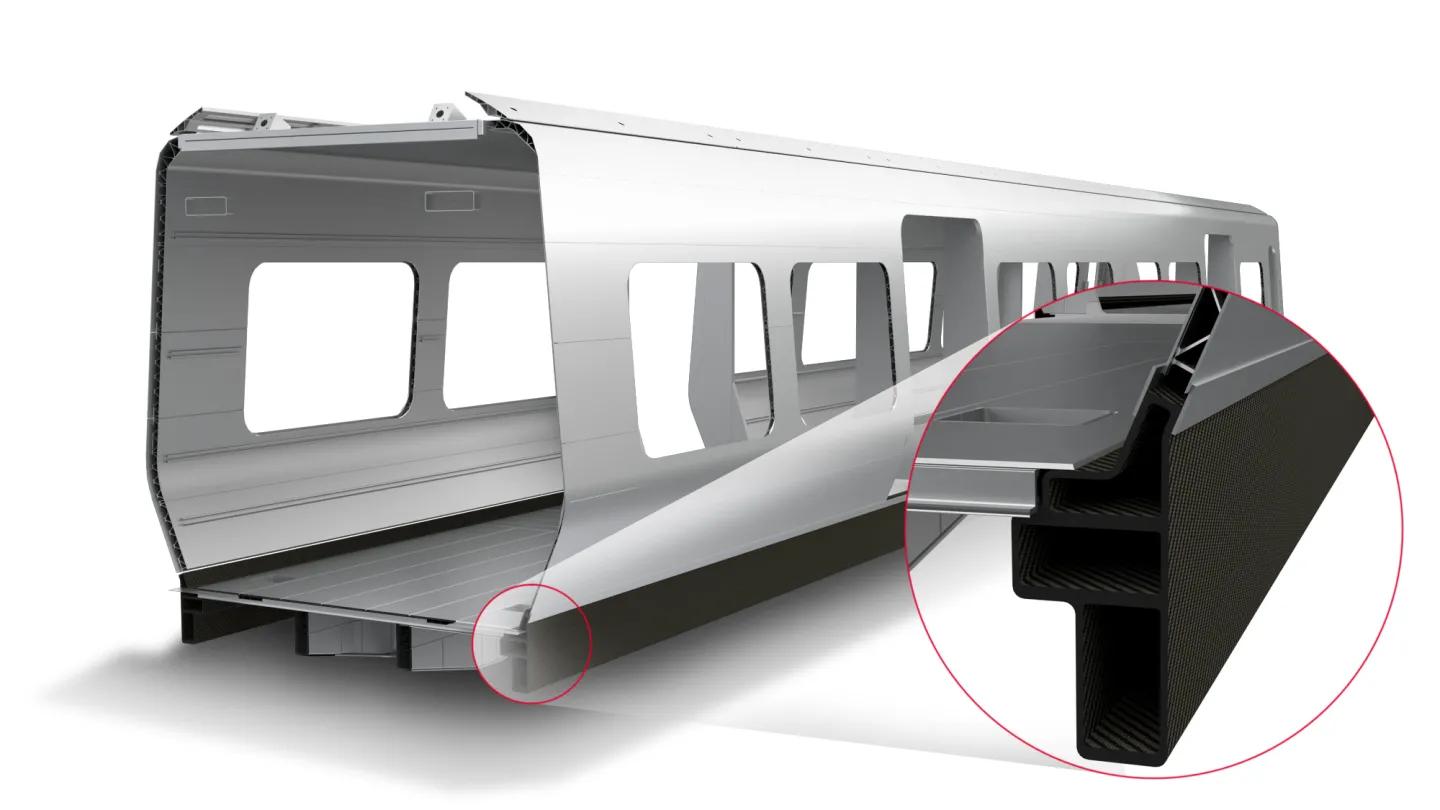

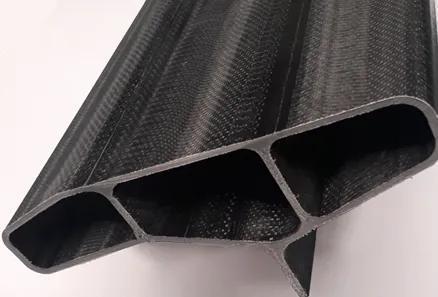

INTEGRAL

Development and series production of competitive rail vehicle roofs in lightweight FKV construction

FunPul

Inline functionalization of pultrusion profiles

In the project, the partners are developing a mechanically functionalized lightweight profile for rail vehicle construction under the leadership of Hörmann Vehicle Engineering GmbH (HVE). The hybrid pultrusion profiles are intended to replace extruded aluminum profiles in the body of a rail vehicle while maintaining cost-efficiency and significantly increasing the degree of lightweight construction.

In parallel, a sensor-based functionalized lightweight element for rotor blades in wind turbines (WT) is being developed in cooperation with FiberCheck GmbH (FC). Here, embroidered strain sensors, which are used for monitoring, are integrated into the pultruded functional components. The hybrid profiles for rail vehicle construction are also being enhanced with a sensory function.

RESOLVE

Resource-efficient lightweight solutions based on novel fiber composite semifinished products with bionically optimized fiber orientation

In the RESOLVE research project, the qualification of the technological approaches is now to be advanced in the area of experimental development - and precisely fitting, bionically supported design methods or construction methods are to be developed. The associated significant increase in economic efficiency, resource efficiency and productivity can significantly expand and diversify the fields of application for continuous fiber-reinforced thermoplastic fiber composite materials, thereby bringing intelligent and climate-friendly lightweight construction solutions into widespread industrial use. Due to the high level of interdisciplinarity of the development content, a cross-industry knowledge and technology transfer is promoted - in line with the funding policy objectives - which makes a valuable contribution to securing Germany as an industrial location. In addition, the project can make a significant contribution to achieving the climate targets, as described in Chapter V.

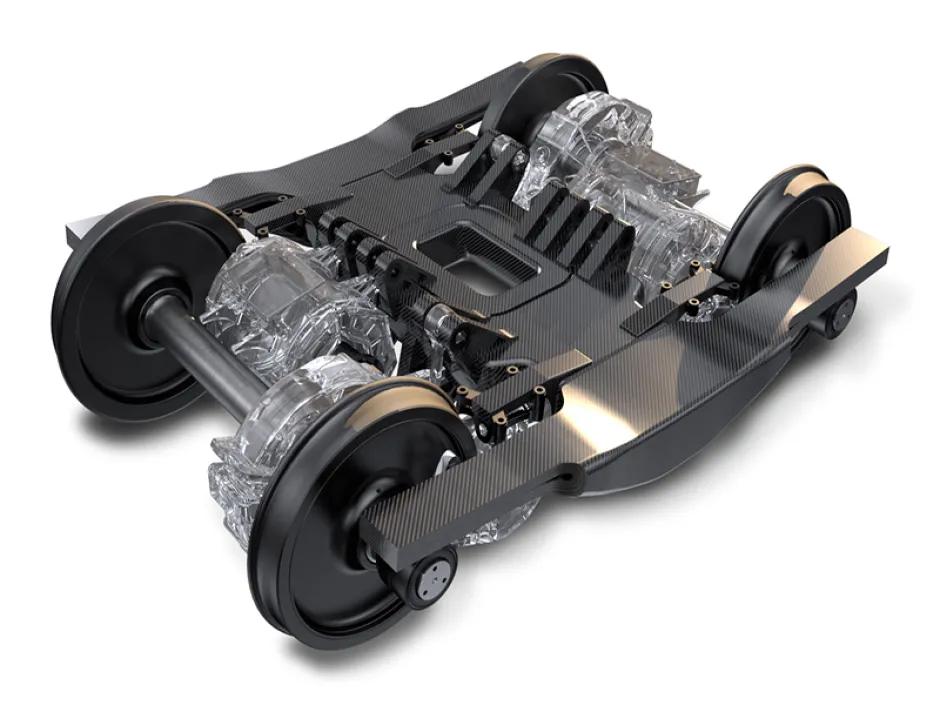

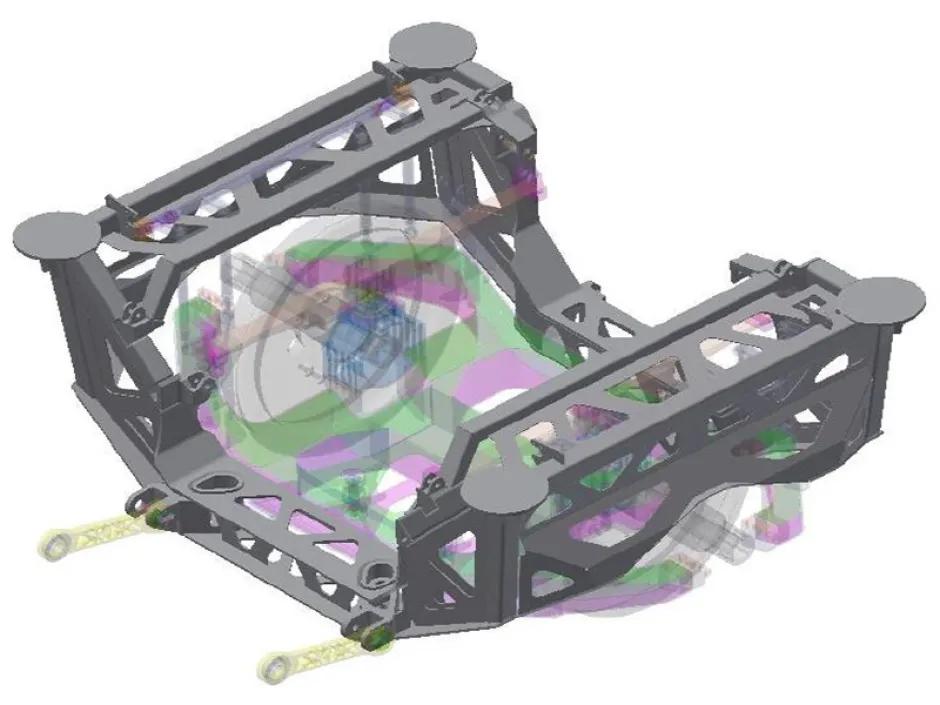

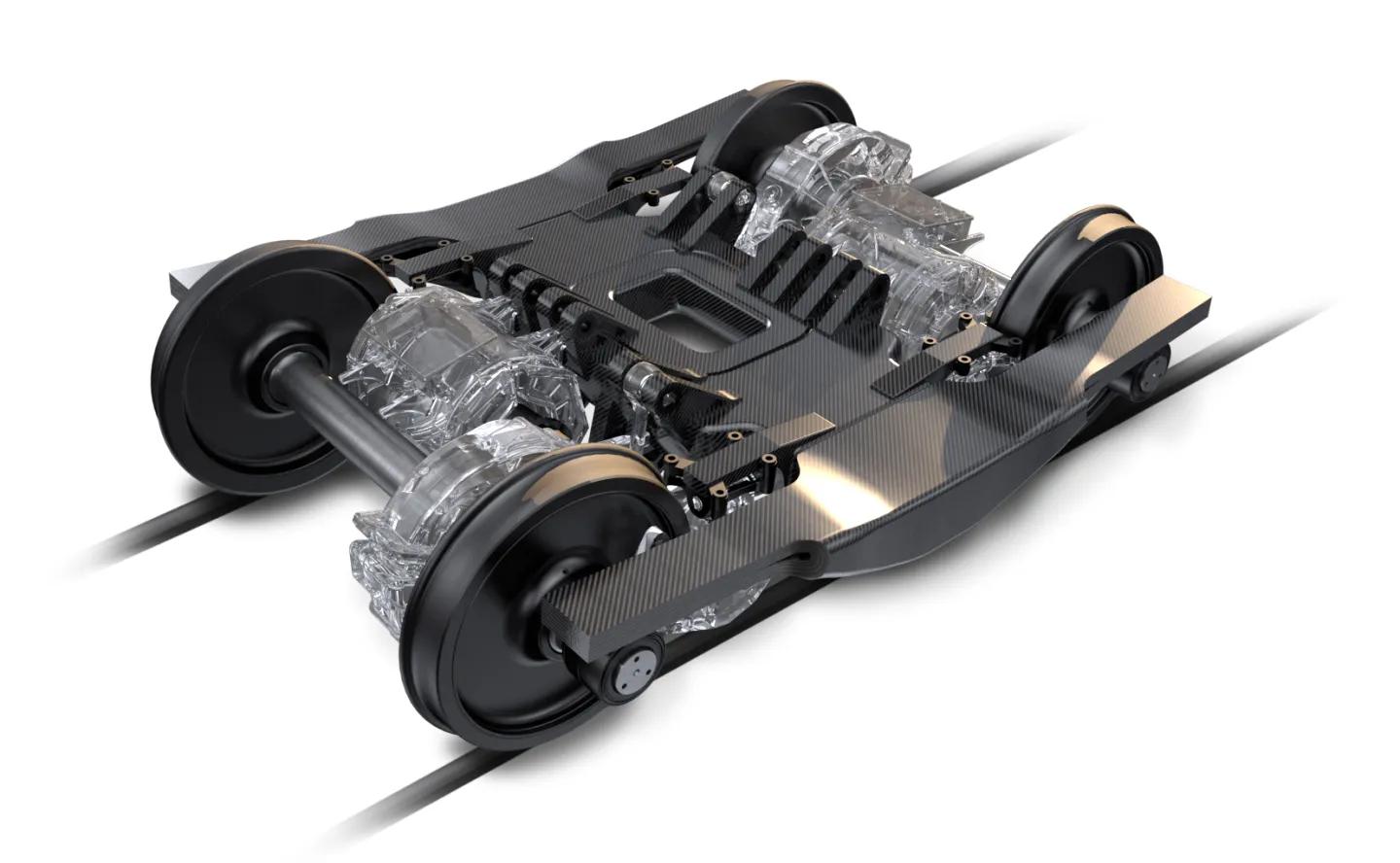

Hybrid Bogie – completed research project

Bogie with a frame of carbon fiber reinforced plastic (CarbonBOGIE)

Project period: Jan 2019 - Sep 2022 | Project partners: KVB Institute, Fraunhofer IWU, IMA Test Center

With the hybridBOGIE joint project, HÖRMANN Vehicle Engineering intends to research a latest-generation bogie (DG). The aim is to create a bogie with improved parameters in terms of functionality, weight, mileage and noise emissions. This is to be achieved by researching a hybrid mixed design with vibration damping materials and the active integration of suspension elements into the functional structure of the bogie frame (DGR).

The aim of the project is the development of a manufacturing process for the production of a hybrid fiber bogie frame including the demonstrator and sample construction. The design and integration of a sensor network into the bogie frame for permanent component monitoring is also part of the subproject. A concept to protect the impact-sensitive frame structure from stone chipping is also being researched.

The project was funded by: EFRE and SAB

Thermopre+ – completed research project

Manufacturing technology for the reliable processing of load-compatible effiLOAD preforms for flame-resistant interior applications

Project period: Oct 2018 - Oct 2022 | Project partners: Fraunhofer IWU, Hegewald & Peschke, Renolit SE, Norafin, Cetex

In a joint project with regional industrial partners and research institutes, lightweight fiber-plastic composites (FRP) with their special mechanical properties (high-performance polymers) are to be processed into semi-finished products, so-called prepregs, and used in high-performance structural components in automotive and rail vehicle construction. On the basis of novel load-dedicated fibre composite structures (effiload semi-finished products), HÖRMANN Vehicle Engineering, as the composite coordinator is designing a one-piece innovative streetcar seat. This seat is to be 25 percent lighter than comparable seat components and should considerably reduce the assembly work. Due to their short cycle times in component production, such thermoplastic fibre composite components have great potential for series applications.

The project was funded by: Federal Ministry of Education and Research and PtJ

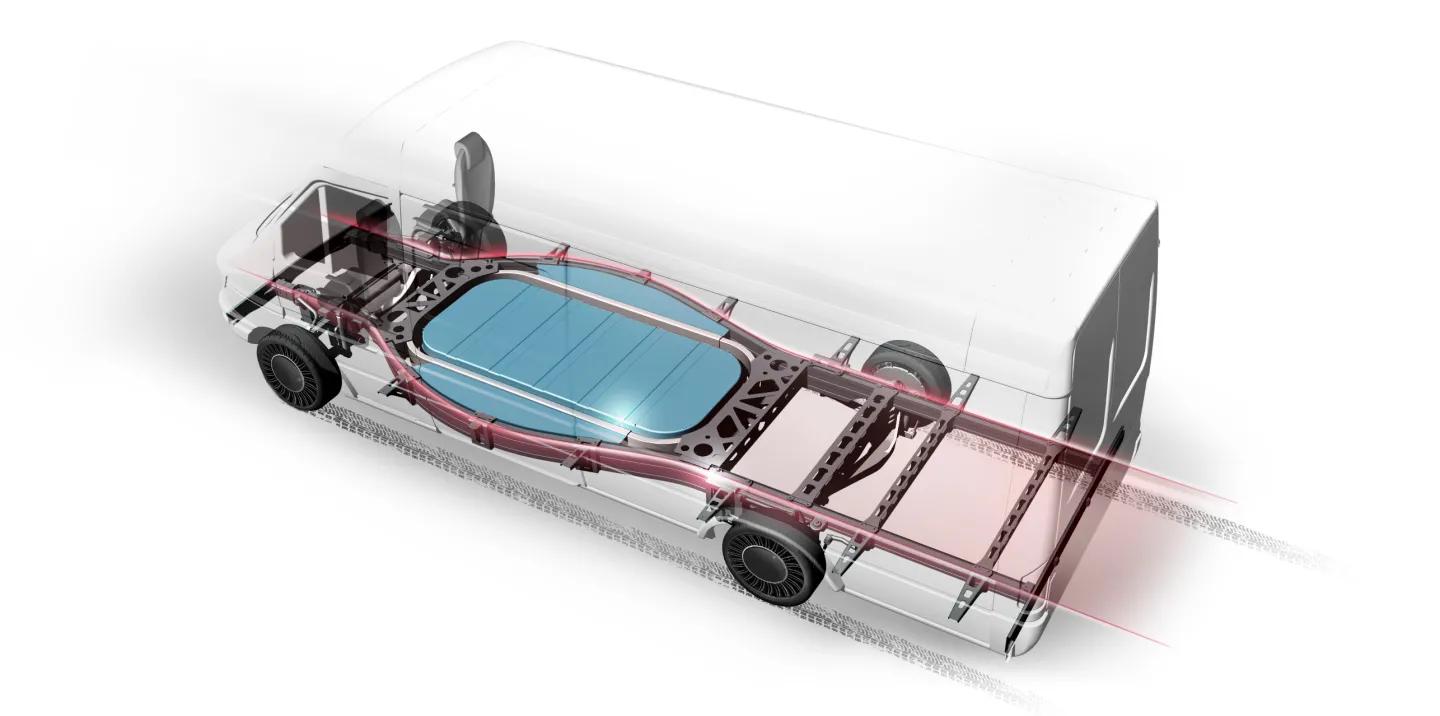

Innovative lightweight chassis – completed research project

HÖRMANN Vehicle Engineering supported HÖRMANN Automotive GmbH in the development of a new integral chassis concept for light commercial vehicles. In terms of production technology, the concept is based on the results of the successfully completed Collaborative Research Centre 666 "Integral Sheet Metal Structures of Higher Branch Order - Development, Production, Evaluation" of the Technical University of Darmstadt. It applies the technologies developed there to vehicle construction for future urban delivery traffic. It uses the branched sheet metal structures to realize new protection mechanisms for energy storage systems of vehicles with alternative drives.