Mechanical Development

Mechanical Development

From the concepts and designs already prepared, we develop the technical solutions in the area of the supporting structure, the chassis as well as the exterior and interior. Of course, all relevant cross-sectional issues that are required for an optimal result are also examined:

- Acoustics

- Fire protection

- Joining Technologies

- Corrosion protection and coloring

- Grounding

- Quality assurance

As a result, we provide you with the necessary documents, which later enable a smooth procurement and production process. This includes in particular:

- Feasibility and verification studies

- Drawings and parts lists

- Delivery and component specifications

- Registration documents

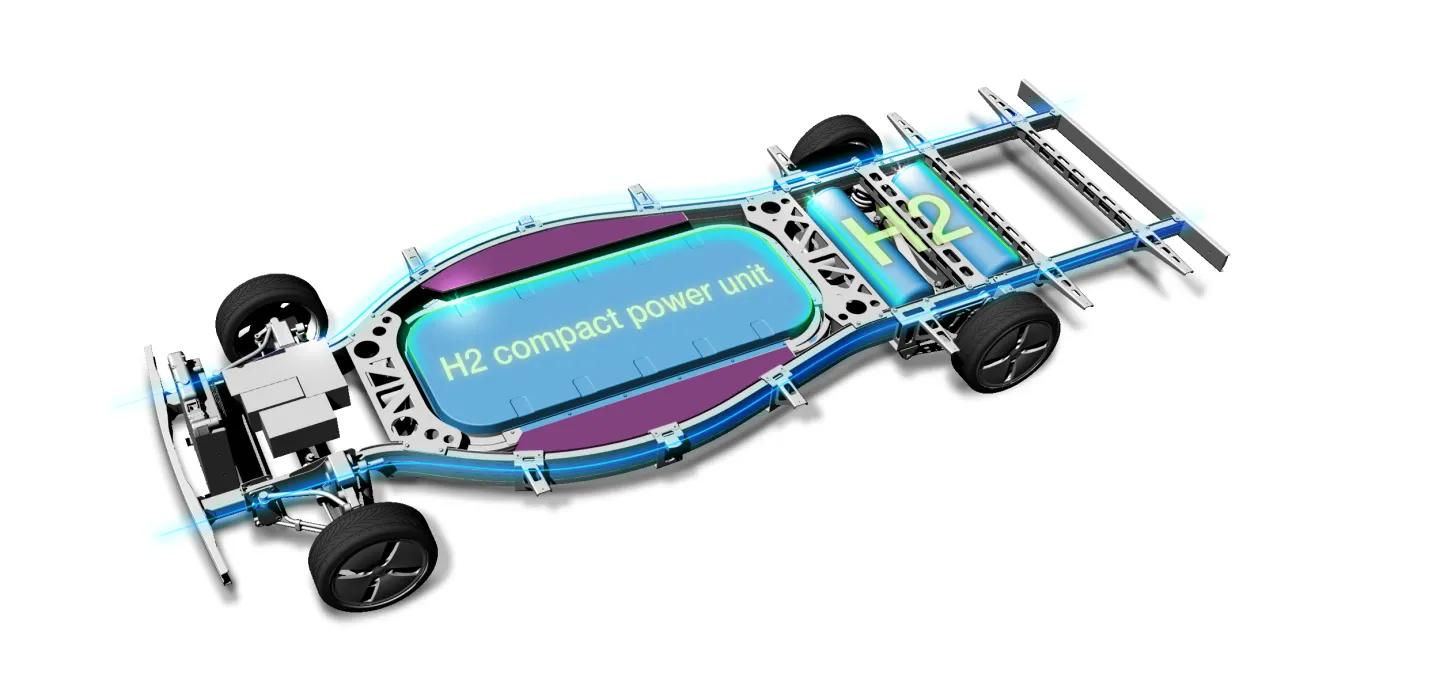

Not only do we impliment current state of the art and production technology, we also strive to offer our customers new technologies to optimize their product. This can be, for example, the integration of new materials to meet the ever-increasing demands for lightweight construction or the integration of new, innovative drive concepts such as the fuel cell. To this end, we work with regional partners in research and development to provide regular training for our employees on the one hand and to offer our customers added value on the other.

Quality

HÖRMANN Vehicle Engineering is a quality supplier. In addition to product quality, values such as safety, adherence to delivery dates, flexibility, speed, optimization and loyalty are particularly important to us. We guarantee this through many years of practical experience as well as through highly qualified employees.

ISO 9001-2015 EN

ISO 9001-2015 DE

Certificate EN 17460:2022-07 | Adhesive bonding of rail vehicles and their components

Zertifikat DIN EN 17460:2022-10 | Kleben von Schienenfahrzeugen und deren Komponenten

EN 15085-2 classification level CL1 (English)

EN 15085-2 Zertifizierungsstufe CL1 (Deutsch)

Certificate DIN EN ISO 3834-2:2006 (English)

Zertifikat DIN EN ISO 3834-2:2006 (Deutsch)

Project Management

From one provider

We understand and practice project management as a holistic view of customer expectations, project tasks and team-internal organizational control responsibility. Our goal: to achieve the best possible results in all technical and economic matters and to implement these in an efficient, open and trustworthy communication with our clients within the given time schedule. Project control and capacity planning as well as the use of resources round off our project management.

Efficient communication and our service:

With our wide range of services and our interdisciplinarity, we can actively respond to new challenges and react quickly and flexibly to individual customer requirements. We guarantee our customers simple and fast communication and coordination.

Project management

For the successful processing of project tasks we maintain close cooperation with the client. This allows us to achieve synergies and effective results at an early stage. Based on our many years of project experience, projects are structured according to requirements and set up with the necessary technical know-how. The project management takes into account the continuous progress of work and the results to be achieved in order to be able to give a precise forecast of the completion. Our goal is always to submit the expected results to the customer on time and in the best possible quality and quantity.

Capacity and ressouce planning

The deployment of specialists in the project is based on the specialized knowledge of the engineers, who take over various activities tailored to the task requirements. The customer can always rely on us to use the best possible competence to handle their tasks. The necessary software systems, technical equipment and other resources are used according to the customer's needs.

Use of resources

The processing of project tasks is based on a set of rules that defines form and format requirements. However, the creative requirements of the task and the creative abilities of our employees are not restricted. The quality management in the project ensures that the specifications for content and presentation correspond to both the customer's ideas and the internal rules.

Test and Commissioning

Troublefree start with our service on site

To ensure that the operation of the products is reliable right from the start, professional installation and commissioning are part of comprehensive engineering. HÖRMANN Vehicle Engineering ensures this smooth start with competence and experience.

Your benefit

- Expert know-how in the critical start-up phase

- Ensuring a smooth and professional commissioning

- Time and cost savings through professional execution and scheduling

Our Performances

- Creation of test specifications and test plan

- Preparation and execution of laboratory and integration tests

- Test logging and archiving of results

- Analysis of test cases with negative result

- Roll-out, test support on the vehicle

References Automotive

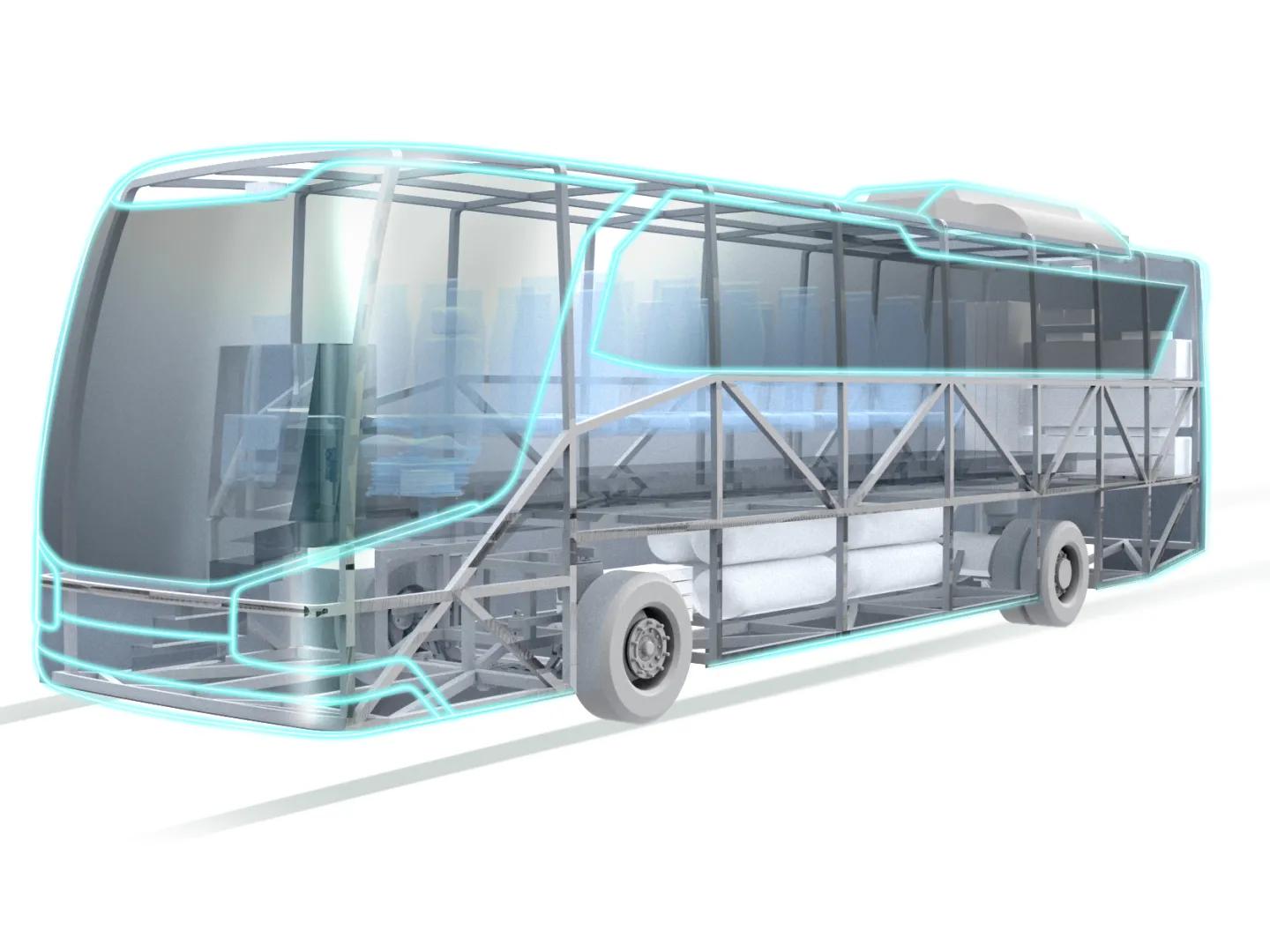

As an experienced engineering service provider, HÖRMANN Vehicle Engineering specialises in "complete development" or individual subtasks for commercial vehicles, buses and motorcycles. Numerous customers benefit from our knowledge transfer from the rail vehicle sector to automotive and vice versa. As a tisax-certified development partner for BMW motorcycles, we develop products from concept to series production and from frame construction to bodywork components. Be inspired by our alternative drive concepts for buses and vans, coupled with comprehensive vehicle concepts, and look forward to exciting solutions for your ideas.

Novel integral chassis for light commercial vehicles

An innovative chassis for urban delivery traffic was developed as a joint project between HÖRMANN Automotive and HÖRMANN Vehicle Engineering. Its unique overall topology is inspired by nature. The universal vehicle platform follows a lightweight structural design approach, which achieves systemic battery protection through the curved frame in combination with multi-chamber longitudinal beams. This reduces the cost and weight of inserting the energy carrier and increases the payload. The production strategy of the beams enables additional cost advantages, as a high variance in the profile course can be mapped without additional tooling.

- Conception

- Mechanical Development

- Calculation and Simulation

BMW – Motorcycle develompent

As a development partner, HÖRMANN Vehicle Engineering develops body components for BMW Motorrad from concept to series production. Various components such as cladding, seats, wind shields, fuel tank and luggage system are designed by us in a function-, tool- and production-oriented manner up to series development. A high-quality, technically optimized and cost-effective component design, taking into account all relevant requirements, is important to us. The component solutions, e.g. made of plastic injection moulding and aluminium die-casting, are specified by us and joint plans with functional dimension concept (FMK) are created and coordinated and documented in close cooperation with BMW Motorrad.

- Conception

- Mechanical Development

- Calculation and Simulation

- Functional System Development

ESPRIT: electrical lightweight construction - vehicle composite

The Easily diStributed Personal RapId Transit (ESPRIT) project was aimed at developing a special lightweight electric L-class vehicle that could be stacked together to save space and driven as a road train. It is part of the Horizon 2020 program of the European Union. Up to 8 ESPRIT vehicles can be nested in one truck train to allow efficient fleet redistribution and an intelligent, balanced, and cost-effective transportation system. A total of 20 partners from 7 countries were involved in the project.

- Vehicle Development (Design, CAD Modelling, Coupling Construction, Prototyping)

- Vehicle Automation

- Vehicle Maintenance

CRRC ART-Tram (Autonomous Rail Rapid Transit)

For the Chinese rail vehicle manufacturer CRRC, HÖRMANN Vehicle Engineering was involved in the development of the innovative rail-free tram. For the hybrid model consisting of bus and tram, we prepared concept studies and examined various functional designs for installation space and freedom of movement. In addition to the design integration of electrical components and the drive train, we were responsible for the technical calculation and simulation of individual parts and assemblies.

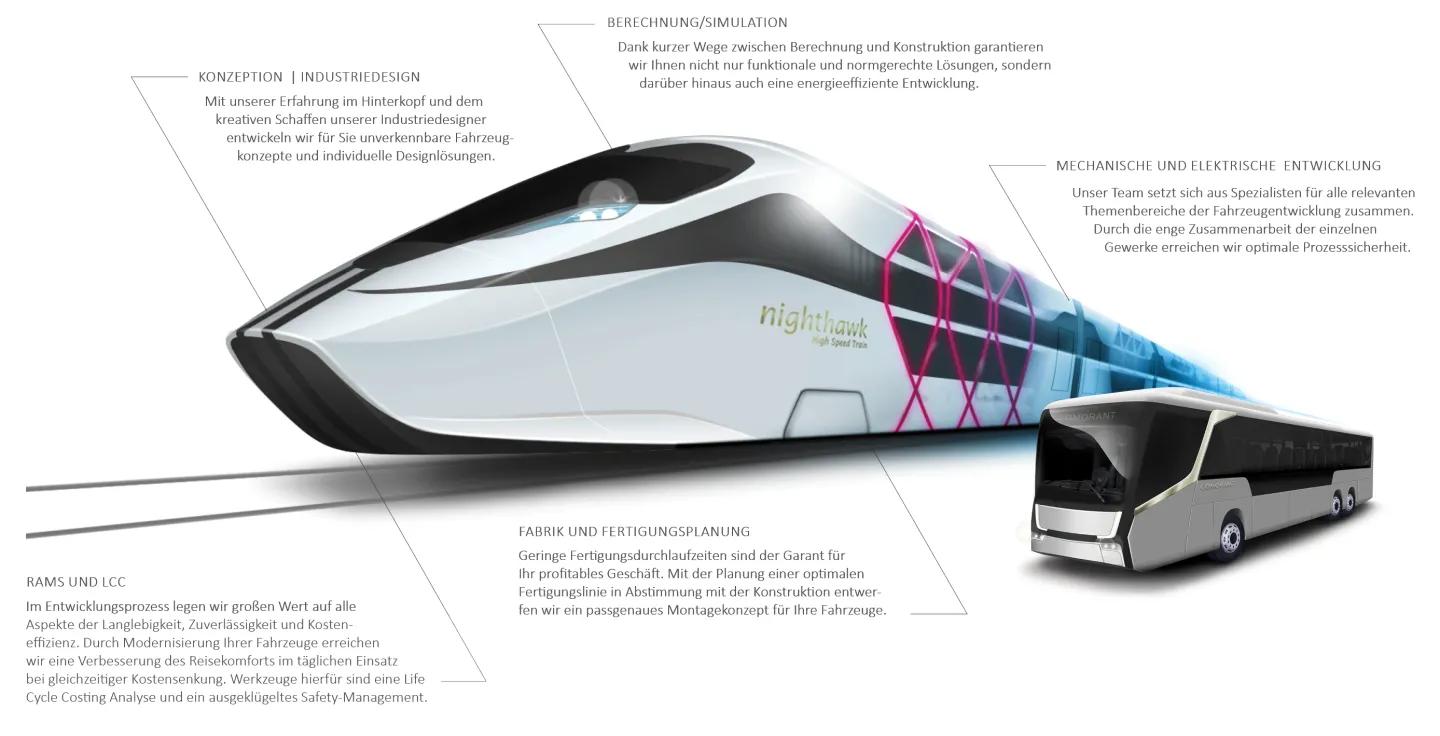

References Rail Vehicles

With more than 30 years of experience in the rail vehicle sector, HÖRMANN Vehicle Engineering has successfully supported numerous international customers with its complete vehicle competence and/or as an engineering partner. Get an overview of our rail vehicle references: from streetcars, metros, EMUs and high-speed trains to locomotives and special vehicles.

TRSC - Low-floor tram for New Taipei City

The Taiwanese manufacturer Taiwan Rolling Stock Company commissioned HÖRMANN Vehicle Engineering with the complete development of the new low-floor tram for New Taipei City. Thanks to our concepts, TRSC was able to win the contract in a tendering competition.

- Project Management

- Conception

- Industrial Design

- Mechanical and Electrical Development

- Vehicle Control

- Calculation and Simulation

- RAMS and LCC

- Factory and Production Planning

- Test and Commissioning

SLRVE - Low-floor tram for Shenyang

For the Chinese rail vehicle manufacturer Shenyang Liyuan Railway Vehicle Equipment Co. (SLRVE) in Shenyang, HÖRMANN Vehicle Engineering developed a modern 100 percent low-floor tram. The HÖRMANN company was responsible for the complete vehicle development, from project management, conception, industrial design, the entire mechanical and electrical engineering services, calculation, RAMS and LCC.

As SLRVE equipped its workshop with the latest production technologies parallel to the development of the vehicle, we were able to use the entire range of state-of-the-art workshop equipment and to tap into savings potential in terms of production time and costs.

- Project Management

- Conception

- Industrial Design

- Mechanical and Electrical Development

- Vehicle Control

- Calculation and Simulation

- RAMS and LCC

CRRC Changchun - Low-floor tram for Shenyang

HÖRMANN Vehicle Engineering developed China's first low-floor tram for CNR Changchun. 20 trams have been in operation in Shenyang since 2014.

The special features of this project included built-in underfloor panel heating and an extremely large (raised) panorama window, as well as newly developed LED lights in the front area. With an ambitious schedule, the first low-floor tram was ready in time for the China National Games 2013.

- Project Management

- Conception

- Industrial Design

- Mechanical Development

- Calculation and Simulation

- RAMS and LCC

- Test and Commissioning

Solaris – Leipzig XL

The Polish tram manufacturer Solaris commissioned HÖRMANN Vehicle Engineering to develop the body shell of the new Leipzig tram. The project was the second for Solaris after the bodyshell development for the first Solaris tram in Poznań.

- Conception

- Mechanical Development

- Calculation and Simulation

- Test and Commissioning

Heiterblick - tram VAMOS Dortmund DWS21

For Heiterblick, HÖRMANN Vehicle Engineering is planning and designing the new and modernization vehicles based on the existing fleet of B80 cars in Dortmund.

Special challenges are the transfer of an existing vehicle concept and a given vehicle structure into a new, independent vehicle development. The light rail vehicles will be provided with improved passenger comfort by ventilation as required, larger multifunctional areas and by the method of raising and lowering the vehicles on the platform, which is used for the first time in light rail vehicles.

Against the background of a comfort-related increase in unladen weight and higher payloads, compliance with the permissible gross vehicle weight and permissible axle loads is also being realized.

- Project Management

- Conception

- Mechanical Development

- Integration of the Electrical Development

- Calculation and Simulation

- RAMS and LCC

- Test and Commissioning

Heiterblick | Vossloh Kiepe | Alstom – TW3000 tram Üstra Hannover

For the Leipzig tramway manufacturer Heiterblick, HÖRMANN Vehicle Engineering developed the new high-floor tram for the Üstra in Hanover. In addition to the complete mechanical development, the service also included bogie development for Alstom.

- Conception

- Mechanical Development

- Calculation and Simulation

Beijing Rail Transit Technology and Equipment Group RTTE – 160km/h Inter-City-Train

RTTE commissioned HÖRMANN Vehicle Engineering with the development of a multi-system intercity train for a maximum speed of 160 km/h for metro and mass transit operations in the greater Beijing area. The design services covered the complete spectrum from the body shell, interior, exterior, mechanical and functional electrics to on-site support in production.

- Project Management

- Conception

- Industrial Design

- Mechanical and Electrical Development

- Vehicle Control

- Calculation and Simulation

- RAMS and LCC

- Factory and Production Panning

- Test and Commissioning

CRRC ZELC - Double-decker high-speed train in China

CRRC in Zhuzhou commissioned HÖRMANN Vehicle Engineering to develop a double-deck train in aluminium and steel construction for 200 km/h and a single-deck train in aluminium construction for 250 km/h. The double-decker train in aluminium has already been completed as a prototype. The special feature is the lightweight construction with the compliance of 17t axle load.

- Project Management

- Conception

- Industrial Design

- Mechanical Development

- Vehicle Control

- Calculation and Simulation

Bombardier – Dosto 2010

On behalf of Bombardier Görlitz, HÖRMANN Vehicle Engineering developed different complete variants of the double-deck control cars and center cars. The first 3 vehicles for DB Fernverkehr were first shown at InnoTrans 2014. A total of over 600 vehicles of this platform have been manufactured and delivered to date.

- Project Management

- Conception

- Industrial Design

- Mechanical Development

- Vehicle Control

- Calculation and Simulation

Bombardier – Zefiro 380 high-speed train

With around 100 engineers, HÖRMANN Vehicle Engineering worked on the development of the Zefiro, designed for 420 km/h, for Bombardier in Hennigsdorf between 2009 and 2011. We took over the complete mechanical engineering services for the bodyshell and interior design including the extensive calculations and simulations. A further service point was the industrial design, which was carried out in cooperation with the agency Tricon.

- Industrial Design

- Mechanical Development

- Calculation and Simulation

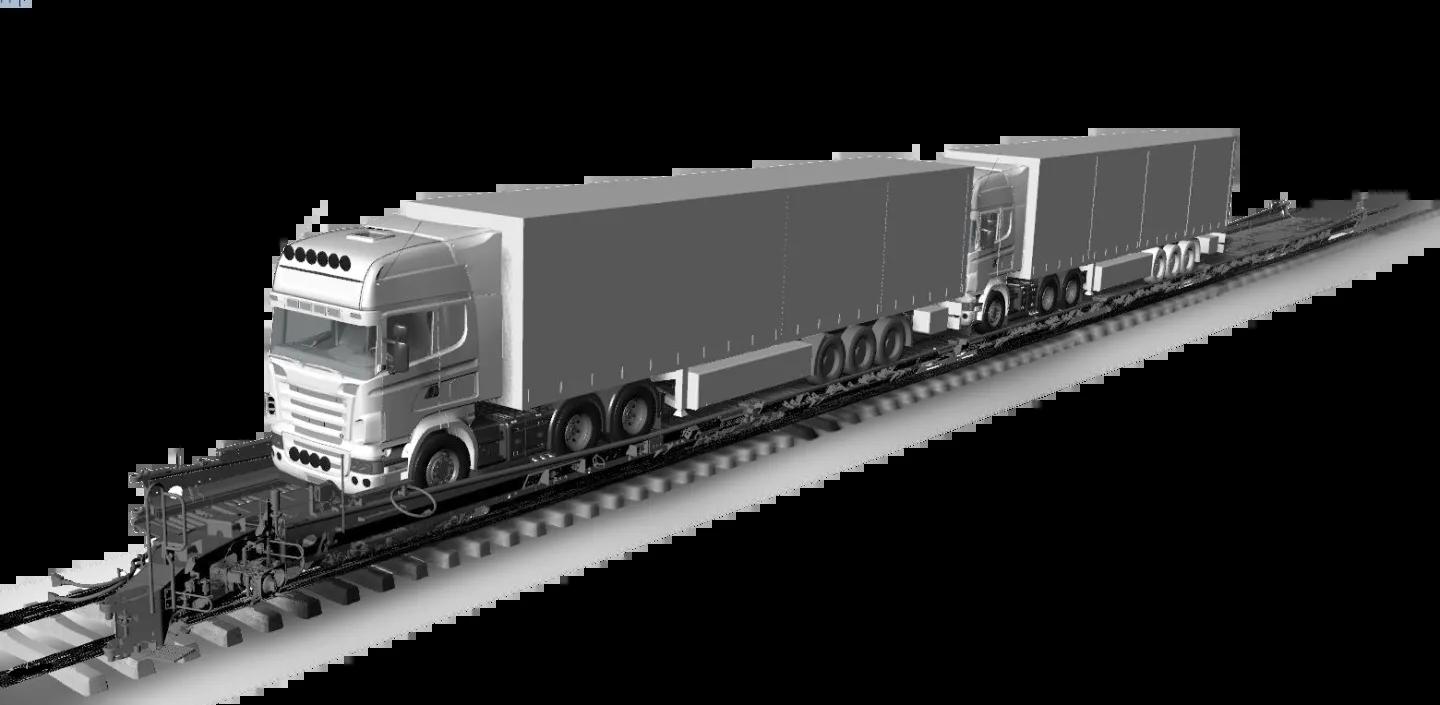

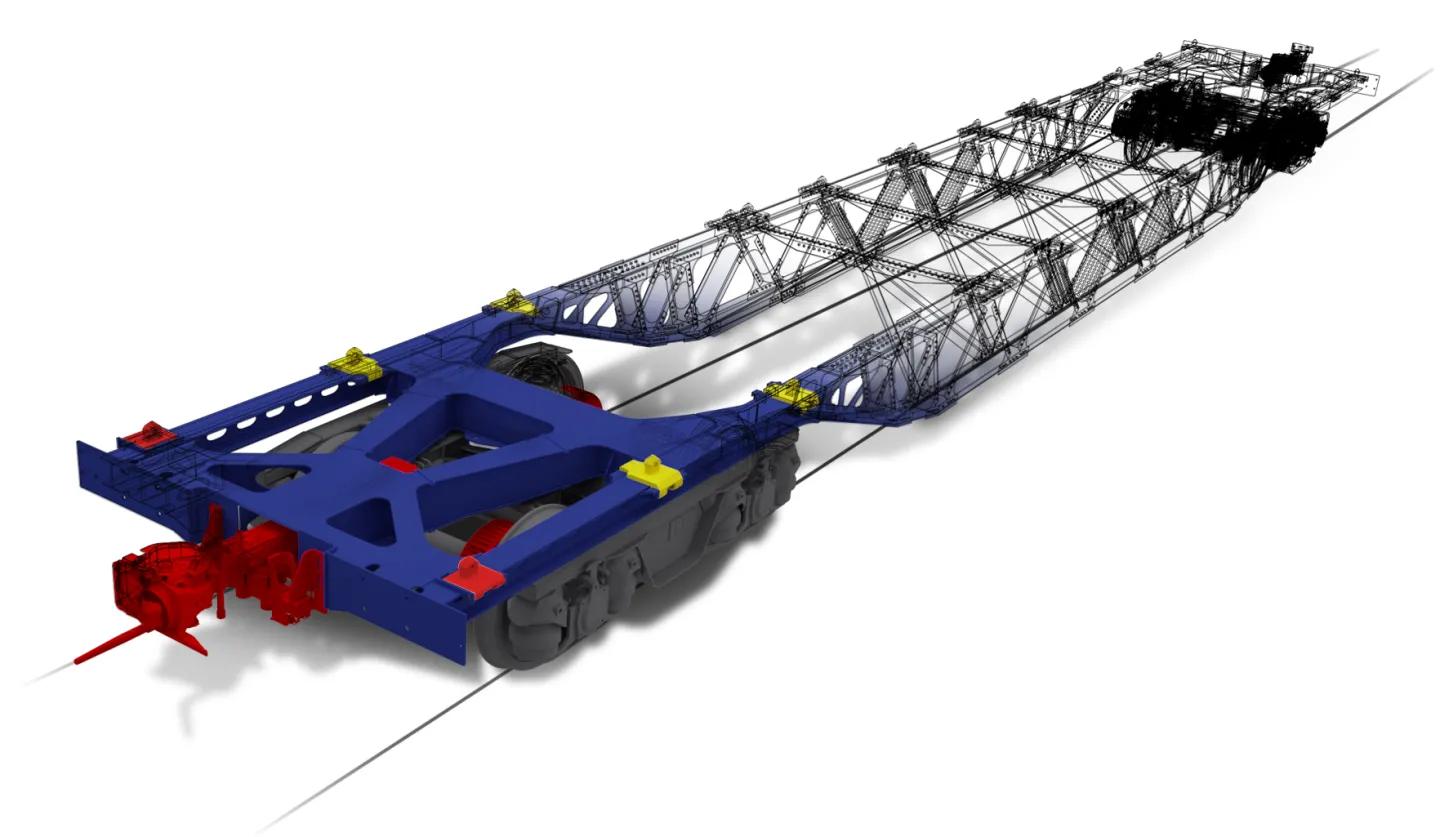

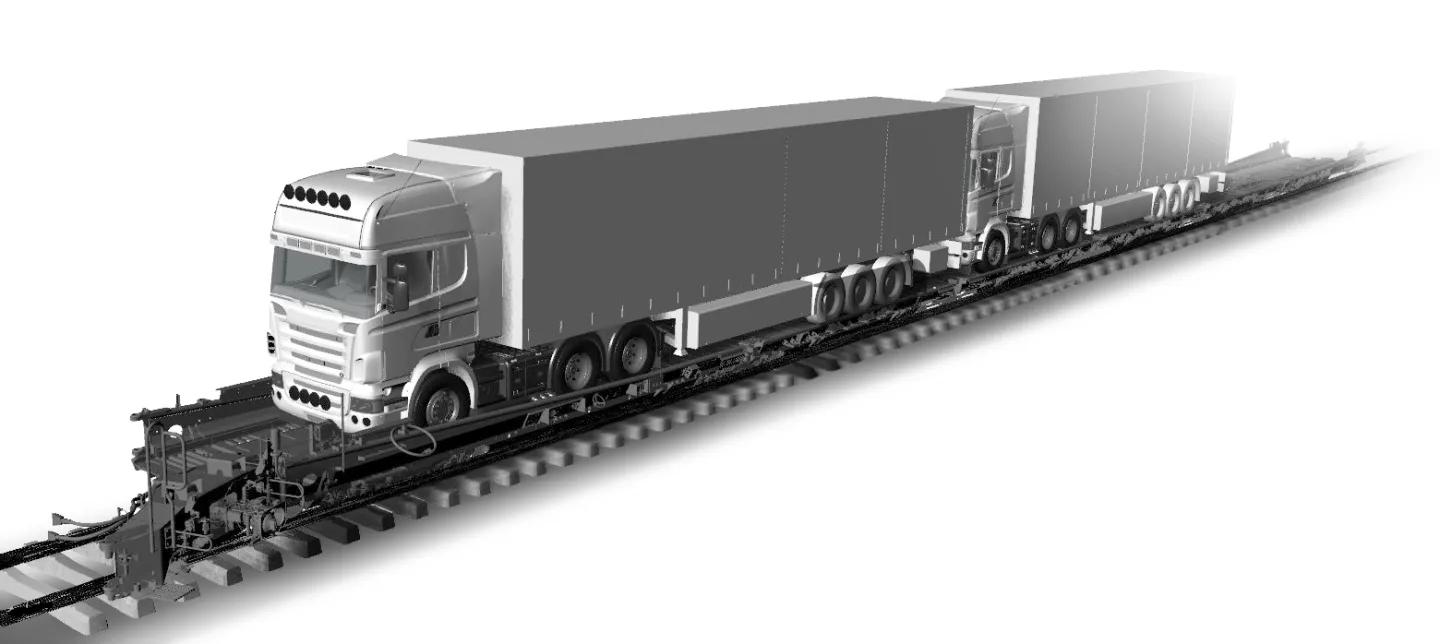

RAlpin – innovative RoLa articulated train

HÖRMANN Vehicle Engineering developed an innovative rolling stock for RAlpin AG, the Swiss operator of the Rolling Road (RoLa). The new rolling stock for the RoMo 2020 is an articulated train for accompanied combined traffic for the transport of entire trucks. The articulated train is to operate mainly in the European area (CH, A, D, IT) and be approved according to the TSI-WAG standard. A main difference of the innovative RoLa articulated train compared to the existing low-floor carrying wagons is that the trucks can be transported across wagons at a distance of 300mm.

SBB Cargo – Lightweight support frame

The task of HÖRMANN Vehicle Engineering was to develop a chassis that combines the attributes of lightweight construction, economical production, a high degree of automation in the manufacturing processes, use of standard parts, and reduction of the welding effort. The modular chassis consists of 3 parts and offers flexible use for various transport tasks and superstructures with higher payloads.

FLC – Locomotive 2EV120 in Russia

For the Russian First Locomotive Company based in Engels on the Volga, the cabin of the 2EV120 electric multi-system locomotive (on the Bombardier TRAXX platform) was developed. HÖRMANN Vehicle Engineering manufactured and commissioned this for the first 4 units.

We manufactured a 1:1 mock-up to investigate the ergonomics and to obtain the necessary certifications in Russia.

Alstom – H3 locomotive

HÖRMANN Vehicle Engineering developed the concept of a new type of hybrid locomotive for Alstom. A very economical and environmentally friendly diesel generator charges the battery and can also drive the electric motor directly for peak loads. At partial load, the locomotive runs on battery power, thus saving 30 to 50 percent diesel in this version compared to conventional 700kW shunting locomotives. This platform concept can also be used to implement 3 additional drive solutions (dual engine / battery / DE-1000kW).

Harsco – Special vehicles

HÖRMANN Vehicle Engineering designed the concept development for the Norwegian state railroad:

- Maintenance Vehicles

- Tanker Vehicle

- Fire-Fighting Rescue Vehicle

- Measuring Vehicle

Our services consisted of the design of a platform for diesel-hydraulic and diesel-electric drive variants of the vehicles, the mechanical arrangement of all components in the vehicles, the integration of crew cabins and work areas as well as in weight management and the preparation of the vehicle descriptions.

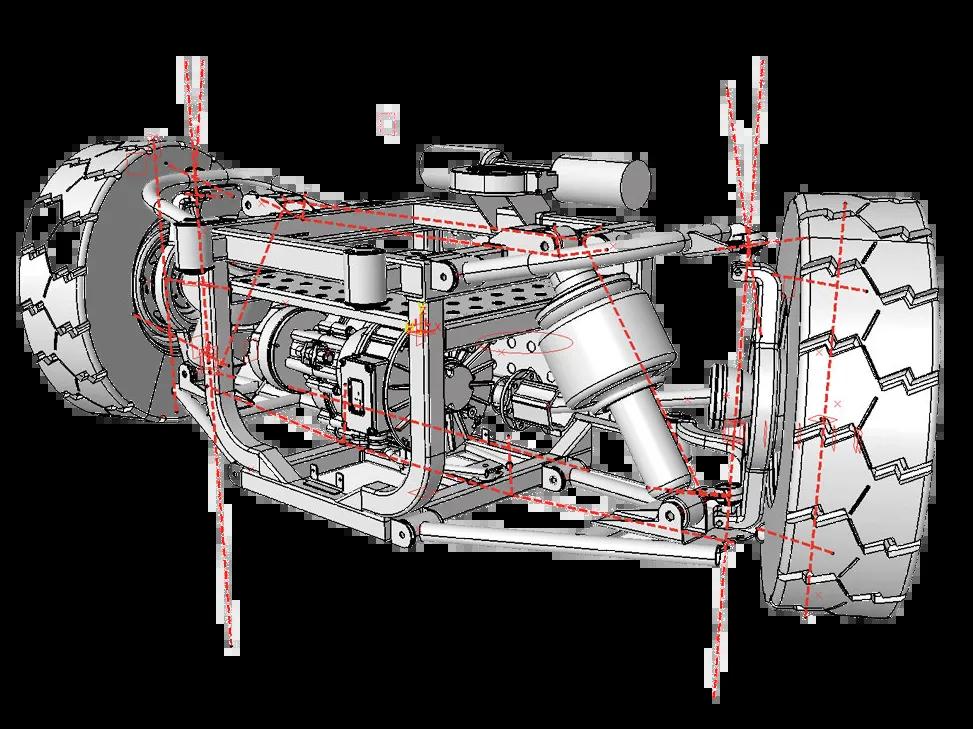

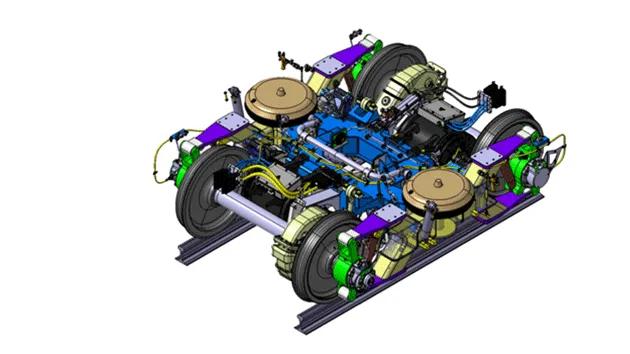

TRSC – Bogie for New Taipei City low-floor tram

For the Danhai LRT project of the Taiwanese rail vehicle manufacturer Taiwan Rolling Stock Co., HÖRMANN Vehicle Engineering developed special motor and running gear with cranked axles for New Taipei City. Special performance requirements had to be met for inclination and acceleration, while adhering to the maximum permissible axle load.

ABB – Drive module for EcoTrain

HÖRMANN Vehicle Engineering was responsible for the project planning, development and design of a hybrid drive module, which is equipped with a diesel engine-generator unit, a traction motor-transmission unit and cooling systems. This hybrid drive module is used in the EcoTrain, which was converted on the basis of a VT-642. For the prototype of the Ecotrain, we manufactured a hybrid drive module and carried out the electrical and mechanical functional testing.

ABB – Power module for EcoTrain

HÖRMANN Vehicle Engineering was responsible for the project planning, development and design of a hybrid energy module, which is equipped with several battery units, a central transfer box and a traction motor-transmission unit. This hybrid energy module is used in the EcoTrain, which was converted on the basis of a VT-642. For the prototype of the Ecotrain, we produced a hybrid energy module.

References - Overview

Our customers come from the Rail & Road and Research sectors. We work for medium-sized companies, major brands and global corporations. Together with research institutions, we develop future visions for alternative mobility concepts.

Here you will find a selection of reference projects that illustrate our range of services. We would be happy to present selected projects to you in more detail.

Convince yourself of our range of services with a selection of references. Please contact us!

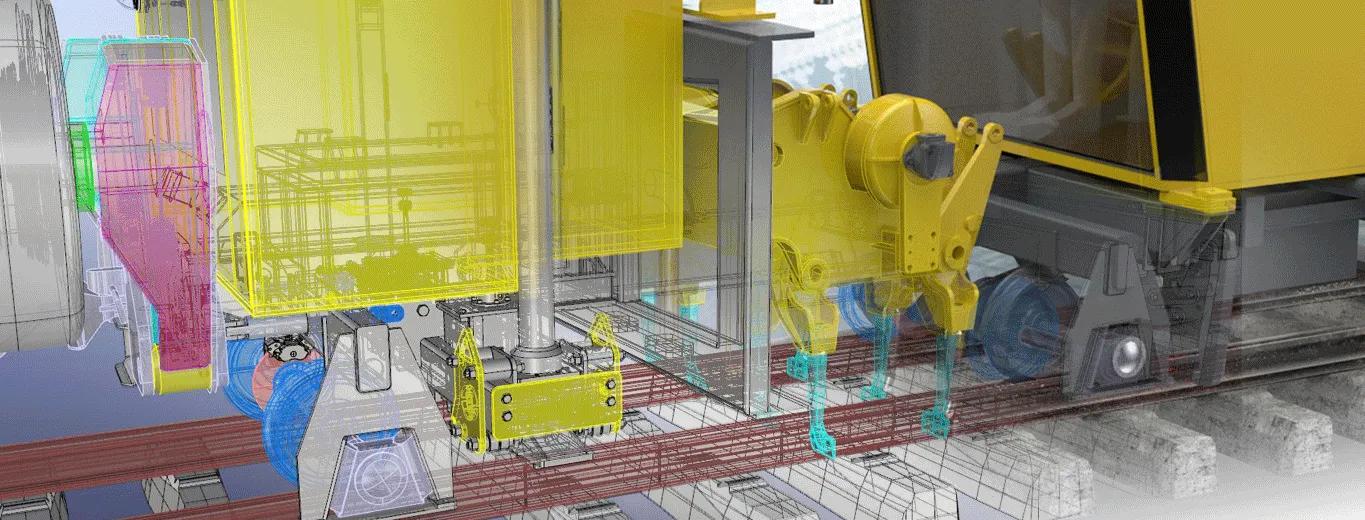

Production Planning and Fixture Development

Beyond product development...

We do not leave our customerson their own with their product, but accompany them with our manufacturing and logistics strategies to optimize their production facilities for the latest products. As a development partner, we also take over the design, development and detailed planning of the production of the new vehicle and ensure efficient implementation management.

In order to make production economical and competitive in the long term, we pursue a holistic approach to creating flexible automation solutions.

- Planning of the production process based on the defined technologies and design requirements

- Definition of the degree of automation depending on quantity and quality

- Simulation of the factory processes by integrating the production lines into the existing factory or the planning of new buildings

- Planning of logistic processes

- Construction of devices and equipment

RAMS and LCC

Efficiency for your technical product

The RAMS management - normatively anchored in the development by the EN 61508, EN 50126, ISO 26262 etc. - supports the development process with regard to reliability, availability, maintainability and especially safety (RAMS).

The implementation of the processes, which are not least relevant for approval, influences the development through the applied methods so positively that the product quality is increased and time and costs are optimized.

"Life Cycle Costing" is a proven means to commercially evaluate especially high capital goods with long life cycles. In the field of vehicle development, especially rail vehicle development, these analyses are used by end customers as a universal basis for product comparison.

Furthermore, we apply methods such as "target costing" in the development process in order to sound out the economic optimum between development, production and operation of the products

- Safety management: danger and risk analysis, design of safety architectures, maintenance of proof of safety according to EN 50129 or CSM (Common Safety Methods) according to EU 402/2013

- RAM analysis for improved reliability, availability and maintainability using RAM analysis, FMECAs, FTAs and proof of availability requirements

- Creation of maintenance concepts, plans and instructions as well as the operating manual

- Implementation of life cycle costing analyses (LCC)

Calculation and Simulation

Security for your product

HÖRMANN Vehicle Engineering GmbH calculates, evaluates and optimizes your products and processes using state-of-the-art simulation technologies. This enables us to identify weak points, and also to identify potential for improvement, e.g. savings. Interdisciplinary cooperation in the development of rail vehicles and commercial vehicles enables us to participate in the development of a product at an early stage and thus to design an efficient product development process.

- Structural mechanical analyses, e.g. strength, stability, vibrations

- Design of fasteners, e.g. screws, welds, adhesives

- Crash analyses and multi-body simulation

- Design of fiber composite materials

- Preparation/supervision of strength tests