Roof structure made easy

Roof structure made easy

New drive technologies, systems and functions - modern light rail vehicles and streetcars are becoming increasingly complex, but also heavier. Where weight is added, savings have to be made elsewhere. Together with the project partners RCS GmbH Rail Components and Systems, Arno Hentschel GmbH and the Fraunhofer Plastics Center Oberlausitz FKO, Hörmann Vehicle Engineering GmbH has taken on this problem.

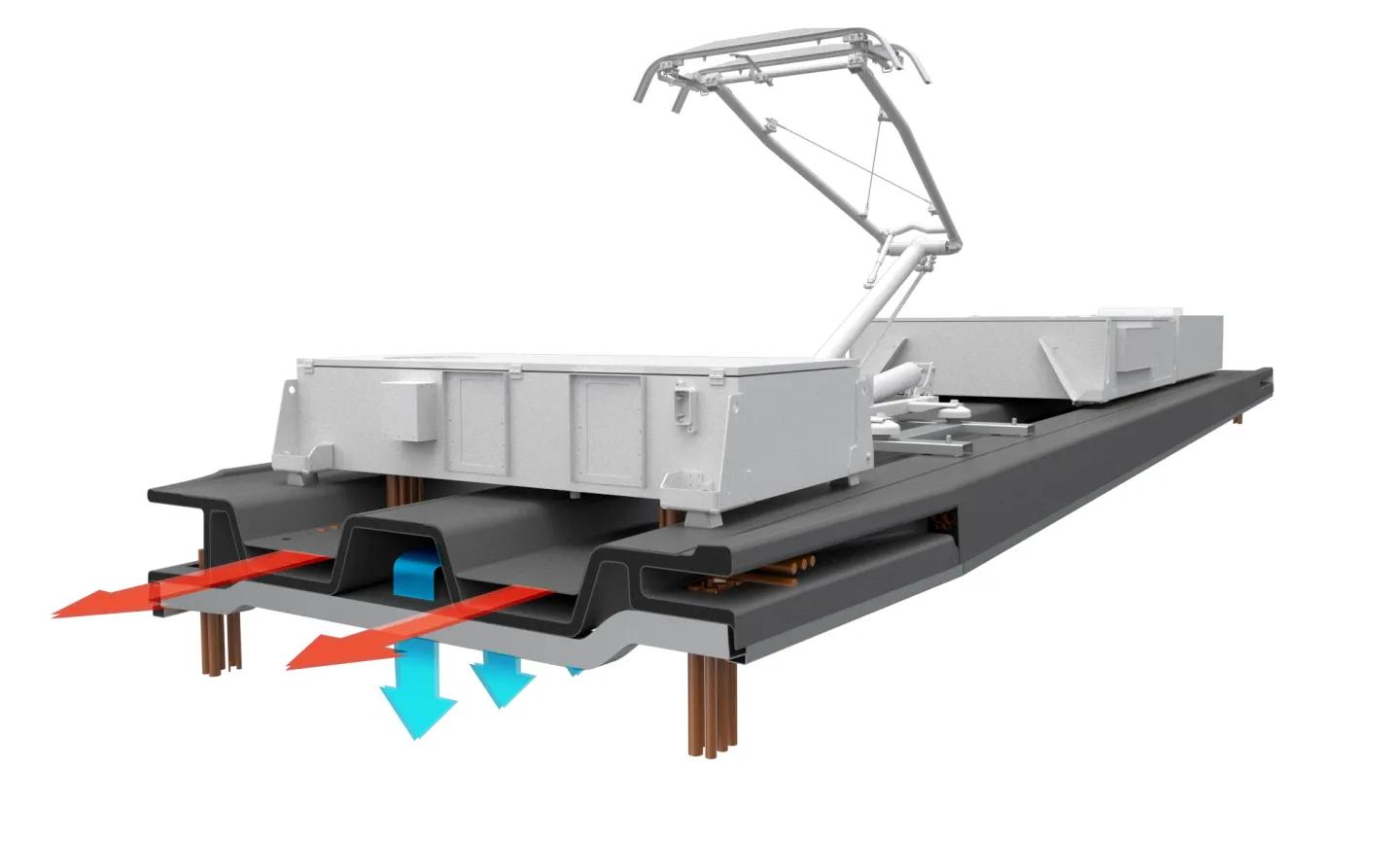

The "INTEGRAL - Integrative lightweight roof for rail vehicles" project has been working for a year on the development of a highly integrative lightweight roof structure made from a load-optimized fibre-plastic composite. The project focuses on the development of competitive rail vehicle roofs with a significant weight reduction (-40%) and lower assembly costs compared to conventional roof structures in weight-intensive differential construction, as well as the development of economical production and assembly processes suitable for series production.

"The achievement of a high degree of lightweight construction of the roof structure is achieved through consistent utilization of lightweight material and structural construction with load-appropriate FRP construction methods as well as lightweight functional construction through the integration of add-on parts and load introductions," explains Reymond Kreuziger, Project Manager at Hörmann Vehicle Engineering.

Modern low-floor streetcars in particular place high demands on the roof structure. This is not only crucial for the reinforcement of the overall vehicle structure, but must also absorb high static and dynamic loads from the various vehicle units, such as energy storage units, current transformers, braking resistors, pantographs, air conditioning units and telecommunications equipment, which are mounted on the vehicle roof due to the limited installation space in the chassis area, among other things. The high mechanical loads in turn result in weight-intensive roof structures, which further increases the center of gravity and thus leads to unfavorable handling and high stress on the vehicle as a whole. This should be avoided and makes consistent lightweight construction while maintaining structural stability all the more important.

In order to demonstrate the design and technological project results, the first prototype FRP lightweight roof structures will be produced at RCS GmbH at the beginning of next year and then tested under realistic conditions at the Fraunhofer Plastics Center Oberlausitz. Together with the associated partner HeiterBlick GmbH, the production of a demonstrator roof and the prototypical integration into a modern low-floor vehicle is also planned.

"Without new innovative lightweight construction solutions, the operator requirements for maximum comfort and environmental friendliness with constant maximum axle loads per vehicle can no longer be met," says Frank Salzwedel, Managing Director of Hörmann Vehicle Engineering GmbH, confidently.

Project partners:

Funded by: